Advanced Adhesion - Poach

#1

Posted 01 October 2023 - 12:01 AM

Polach's adhesion seems to fit the measured adhesion properties of locomotives more closely and his work is considered by most to be "industry leading".

It also has the benefit of allowing for future inclusion of some track properties (would require changes to track database) to simulate the adhesion capabilities of different track construction types and designs, as well as different wheel physics for the locomotive. It also makes allowances for different curve conditions.

Hopefully it should appear in the most recent Unstable version shortly.

It may require some adjustment in driving practice as rapid application of power to the locomotive may cause slip. The wheel slip alarm triggers as soon as the wheel slip moves into the slip zone. The reduction in MotiveForce will not be dramatic if is is only slightly past this point, however if it is much further past the point, then significant loss of power at the wheels will occur.

Those who wish to just see trains run without focussing on the physics might be best to use simple adhesion.

To initially get a feel for the operation, it is recommended that the following two pieces of CTN stock be used before trying out your own stock.

Norfolk Southern diesel - this unit will slip if rapid increases of throttle setting are applied or maximum power at low speed (<10mph).

New York Central steam locomotive - this locomotive was very slippery (had a FoA < 4) so it will slip if maximum power is applied at low speed, or power is not decreased as it speeds up.

If any issues are identified reference the issue to the above two pieces of stock so that the issue can be clearly demonstrated.

#2

Posted 01 October 2023 - 01:29 AM

That's great to hear, You are still interested, inspired and fruitful.

(there is a typo in topic's title, related to PoLach's familyname - missed "L")

I have a question:

Quote

May we know, please, which of, for instance?

#3

Posted 01 October 2023 - 02:51 AM

Cheers,

Marek.

#4

Posted 01 October 2023 - 01:25 PM

And even with random change disabled, there are still some other differences that aren't quite what I'd expect

- The wheel slip threshold of 0.2 kph (when not moving) is lower than I'm accustomed to, the amount of wheel creep in this model is substantially lower than before. I do think the previous model dramatically exaggerated the typical amount of creep before slip, but I wonder if this has gone too far in the other extreme?

- Wheel slip % doesn't seem to accurately measure how close the locomotive is to slipping, I'm seeing slip values of 30% indicated when the locomotive is just a few hundred pounds of effort away from slipping (I'd expect the slip % here to be in the high 90s), at which point the slip % rapidly shoots upward and slipping begins. This gives no time for the warning at 70% to actually trigger.

- Larger than usual number of substeps in many situations, especially at lower speeds. Unclear if that's just the nature of this algorithm, but maybe the max of 50 isn't enough?

- Slip happens on locomotives that are moving but coasting/producing very low force. It seems the axle model is convinced these low forces are enough to exceed the adhesion available to the axle (somehow 2,500 pounds of force on a 400,000 pound locomotive was registering as requiring 22% adhesion from the wheels)

- This isn't quite compatible with 'ORTSSlipControlSystem ( Full )' as while using slip control system I've found situations where it limits tractive effort lower than what the new adhesion system thinks the locomotive can handle, and other situations (particularly in snow) where the slip control system fails to limit adhesion enough and slip happens anyway. That behavior will need an update.

#5

Posted 01 October 2023 - 09:45 PM

Weter, on 01 October 2023 - 01:29 AM, said:

Weter, on 01 October 2023 - 01:29 AM, said:

It will be necessary to do some research to determine exactly what values might need to be modified by the user. But until the track database can accept different values there is probably not a lot of value in trying to add them. The inputs will need to be simplified as much as possible to allow most users to identify them for use.

Here are a couple of references that might help to get the ball rolling:

Railway Track Design: A Review of Current Practice

Kalker Model - see the Overview of the Computational Model

#6

Posted 01 October 2023 - 10:42 PM

pschlik, on 01 October 2023 - 01:25 PM, said:

pschlik, on 01 October 2023 - 01:25 PM, said:

Random Change - Whilst I haven't looked at the code in detail, I suspect that you may be correct about the rate of change. I agree that 100% values are insane and highly unrealistic.

I personally prefer to run with this feature disabled, and also the "Adhesion Factor Correction" set to 100%, especially during testing as they can skew any test results against real world conditions.

pschlik, on 01 October 2023 - 01:25 PM, said:

pschlik, on 01 October 2023 - 01:25 PM, said:

Do you have any test results to support your 0.2kph value?

pschlik, on 01 October 2023 - 01:25 PM, said:

pschlik, on 01 October 2023 - 01:25 PM, said:

As suggested the alarm point is triggered when the transition point is exceeded, so it is possible to have a slip alarm occur with a very small amount of slip occurring. Thus this can mean that the slip alarm is triggered and the reduction in motive force is minimal.

I will have a look at the Wheel slip % calculation.

pschlik, on 01 October 2023 - 01:25 PM, said:

pschlik, on 01 October 2023 - 01:25 PM, said:

pschlik, on 01 October 2023 - 01:25 PM, said:

pschlik, on 01 October 2023 - 01:25 PM, said:

pschlik, on 01 October 2023 - 01:25 PM, said:

pschlik, on 01 October 2023 - 01:25 PM, said:

#7

Posted 01 October 2023 - 11:45 PM

Quote

I agree on using a smooth change. Also I'd prefer a normally distributed random change, instead of uniform random change.

Quote

Polach formula suggests that there is no creep at starting (any creep already reduces output rail force). I think this is realistic.

Quote

Does this happen with DC or AC motors? For AC motors the wheel speed is always kept close to the optimal wheel creep, so it should work in any situation. On the other hand the DC "slip control" is really simple and will fail with the new model.

I suspect the rest of issues are caused by numerical instability. Unfortunately, that has no easy solution. Increasing the number of integration substeps would have an impact in CPU usage, which is not good. The numerical calculation doesn't like small wheel creeps, that's the reason for the higher creeps in the older model. I was aware of this issue since we started with Polach model, but we needed to test it to confirm the problem.

#8

Posted 02 October 2023 - 12:34 AM

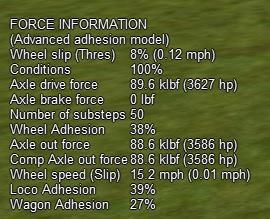

The changes highlight the following:

WheelSlipThreshold - this is the value shown in the brackets in the Wheel slip line.

WheelSlipSpeed - this is the value shown in brackets in the "Wheel speed" line.

Out of interest watch the slip speed as you start the locomotive, a fast throttle acceleration will push the slip speed up til it exceeds the threshold speed, whereas slow throttle accelerations allow it to "settle down" again and return to a low slip (creep) speed.

#9

Posted 02 October 2023 - 06:37 AM

steamer_ctn, on 01 October 2023 - 10:42 PM, said:

steamer_ctn, on 01 October 2023 - 10:42 PM, said:

Can you give me the test scenario steps that you are following, and advise which CTN test models are giving this response?

I was able to see this on the NS SD70ACe. Spawned one of the consists without advanced couplers on the flat outer loop of the test route, accelerated the train to 30 mph or therabouts, then set the throttle to 0. I think going faster may make this effect more pronounced. After a few seconds, I'd start getting warnings about wheel slip and the HUD would show that the wheel speed was deviating from the true speed. This would happen with adhesion set to 100% with 0% change.

cesarbl, on 01 October 2023 - 11:45 PM, said:

cesarbl, on 01 October 2023 - 11:45 PM, said:

Good point, with the way SlipControlSystem works with the AC motor type, it seems tractive effort is still maximized even with Poach. This does give some amount of wheel creep so is detected as wheel slip, but the actual adhesion remains basically at maximum, so this is unchanged from before. The different setup for DC is definitely less versatile at handling changes in the adhesion model.

#10

Posted 02 October 2023 - 07:59 AM

Log In

Log In Register Now!

Register Now! Help

Help