Water Pumps? an option for early locomotives?

#1

Posted 01 March 2020 - 09:17 AM

With Tim Muirs amazing Civil War models, and many other early locomotives, would there be a chance for water pumps that fill the boiler when the loco is in motion to be added to the eng file? Maybe even steam-driven pumps?

With early locos in the days before the injector you had to use motion-driven pumps or steam pumps, they usually had some regulation valve of some sort to regulate water flow when the loco was running. And during long station stops the loco had to be uncoupled and run back and forth to fill the boiler.

I hope this can be added for those who model or run this time period to make operations a bit more interesting.

#2

Posted 06 November 2021 - 08:45 AM

#3

Posted 06 November 2021 - 08:49 AM

These would be an interesting piece of history.

Did the pumps used later with feed water heaters work on the same principle?

I notice that locos with feed water heaters and pumps always also had an injector, using feed water heater when working and injector when stationary.

#4

Posted 06 November 2021 - 09:27 AM

timmuir, on 06 November 2021 - 08:45 AM, said:

timmuir, on 06 November 2021 - 08:45 AM, said:

I realize there must be numerous requests for added steam locomotive effects in an eng file, and something like cross-head, or wheel- driven water pumps would be low on the list, but here is my vote towards Jon's request. :thumbup3:

Hi Tim,

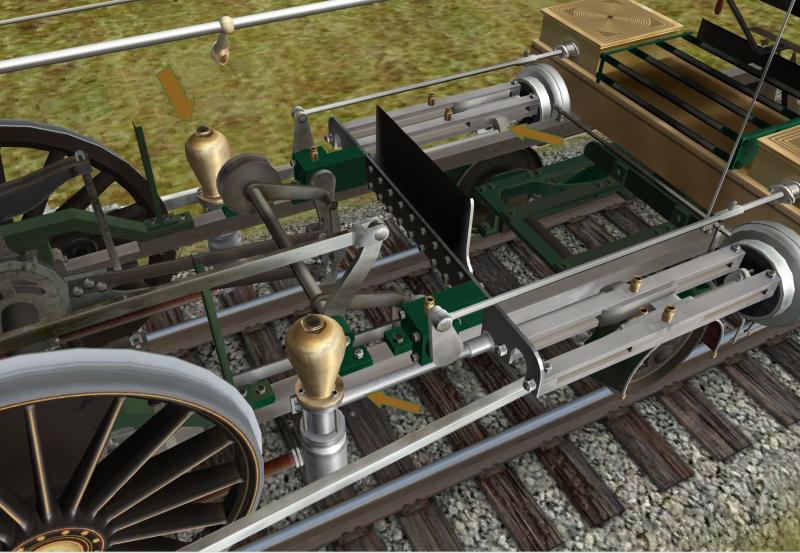

You should release a sperate model for each of your locomotives - just the running gear - so the end user can see the exquisite detail you put into the undercarriage - it's like a fine Swiss watch. Absolutely amazing.

:)

Regards,

Scott

#5

Posted 06 November 2021 - 11:24 AM

#6

Posted 08 November 2021 - 07:37 AM

darwins, on 06 November 2021 - 08:49 AM, said:

darwins, on 06 November 2021 - 08:49 AM, said:

Unfortunately no. The pumps used with feedwater heaters on latter-day steam locomotives were actually steam operated. These systems had only one control--a simple throttle-like valve to control the speed of the pump.

On the Worthington system there are two pumps: one for cold water and one for hot water, but they are both controlled by the same pump throttle valve. On Worthington's model SA system, the cold water pump is automatically regulated by a float valve in the heater chamber, and when the heater is full, steam to the cold water pump is shut off until the water level in the heater drops.

#7

Posted 26 April 2022 - 10:00 AM

Crosshead-driven ram/plunger pumps also make a clicking noise when running, it's the check valves regulating water flow. This could be simulated with a sound stream using its own triggers specific for the ram pumps.

#8

Posted 26 April 2022 - 10:22 PM

Jonatan, on 26 April 2022 - 10:00 AM, said:

Jonatan, on 26 April 2022 - 10:00 AM, said:

Crosshead-driven ram pumps also make a clicking noise when running, it's the check valves regulating water flow. This could be simulated with a sound stream using its own triggers specific for the ram pumps.

In terms of controls, I am assuming the I and O keys (ordinarily used for toggling the injector steam on and off) will be of no use when crosshead pumps are specified instead of injectors, so the only controls needed are the water-flow controls (K, Shift+K, L, Shift+L). Does that sound correct?

By the way, were these pumps single-acting (suction from tank or tender only on one stroke and pumping to boiler on the other) or double-acting (suction and delivery at the same time on strokes in both directions)?

#9

Posted 27 April 2022 - 07:51 AM

I would think they were single acting. There are two balls in the pump, one at the bottom and one at the top. On the suction stroke the bottom ball lifts to fill the pump, on the pump stroke the top ball lifts to let the water into the boiler as shown below:

https://gunt.de/images/datasheet/844/HM-285-Experiments-with-a-piston-pump-gunt-844-zeichnung_einzelheit_1.jpg

So there would only be water being injected on one side of the stroke, or every two quarter revolutions if there's a pump on either side.

For OR I think this is overly complex to make the work of coding it appealing and we could leave it as simply being "loco stopped = no water flow, loco moves = water flow".

For steam-driven reciprocating pumps the normal injector function works fine as you open a water feed and turn on steam for said pump, but an animation triggerd by the injector on/off toggle to show the steam pump in action would be a welcome addition.

Perhaps the relevant parts could be called ORTSWaterPump_xx.

#10

Posted 27 April 2022 - 08:02 AM

The faster the train is moving the faster water can be supplied to the boiler.

Of course at any speed this could be reduced by closing the water valve.

Log In

Log In Register Now!

Register Now! Help

Help