Some thoughts on OR's steam physics

#1

Posted 17 March 2012 - 03:55 PM

But first a hint to improve the driveability of current steam locos in OR. Recent version of OR show a problem when driving steamers. This shows up as the steam pressure dropping markedly when the throttle is opened forcing one to have to "nurse" the throttle up. What is happenning here is the current version of OR implements the BoilerVolume parameter and I have yet to find a loco where this has been specified correctly, most being to small and on occasions WAY to small causing the boiler pressure to drop way to quickly. I have found if one has this aproximately to the free space in the boiler the sim performs quite well. As a rough guide if on uses 90% of the total volumne of the boiler barrel for this parameter one comes out OK. I have analysied the dimensions of a number of boiler s to work out the internal volumne an I have found the above procedure will be accurate to around 10 percent. The syntax parameter in the eng file being BoilerVolume ( "800*(ft^3)" )

As a rough guide a loco weighing around 130 to 150 tons with a power output of 2500KW's the boiler Volumne is aprox 800 to 900 cubic feet ( "800*(ft^3)") in the eng file.The actual calculated free space in the boiler was 845 cubic feet, the rule of thumb calculation as described above came to 800 cubic feet. Two of the locos I regularly drive that are around this size (Victorian Railways H220 and South Australian Railways 500 class) had this parameter around 300 cubic feet and performed patheticly, setting this correctly did wonders.

Questions of course welcomed.

Lindsay

#2

Posted 17 March 2012 - 04:29 PM

Cheers Bazza

#3

Posted 17 March 2012 - 05:46 PM

#4

Posted 18 March 2012 - 04:56 AM

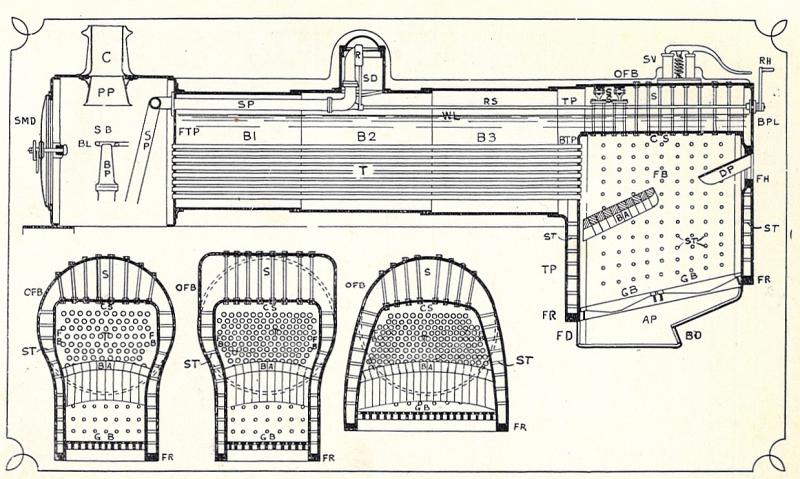

When considering the boiler and it's volume one has to realize that it isn't just a big soda can. Inside that shell are fire tube flues which are of a volume themselves. Their diameter's, length and numbers detract from the total volume. Also one has to consider the fire box volume and the length of the smoke box which contain no water and would have to be subtracted from the boiler volume. Also the mass of the boiler shell and appurtenance's which would be an average of 1 inch of thickness x 2 or 2 inches total must be subtracted.

The true inefficiency of a boiler isn't it's volume as much as it's ability to recover quickly from the demands that are placed upon it. Quick steaming capability is what makes for a good locomotive boiler.

See attached from Wikipedia.

Allen

#5

Posted 18 March 2012 - 11:55 AM

B & O GUY, on 18 March 2012 - 04:56 AM, said:

B & O GUY, on 18 March 2012 - 04:56 AM, said:

When considering the boiler and it's volume one has to realize that it isn't just a big soda can. Inside that shell are fire tube flues which are of a volume themselves. Their diameter's, length and numbers detract from the total volume. Also one has to consider the fire box volume and the length of the smoke box which contain no water and would have to be subtracted from the boiler volume. Also the mass of the boiler shell and appurtenance's which would be an average of 1 inch of thickness x 2 or 2 inches total must be subtracted.

The true inefficiency of a boiler isn't it's volume as much as it's ability to recover quickly from the demands that are placed upon it. Quick steaming capability is what makes for a good locomotive boiler.

See attached from Wikipedia.

Allen

Thanks for the reply but I am ahead of you. The specified volume is what I have called the "free space" the space left AFTER the volumne for the tubes and firebox has been subtracted. The rule of thumb works out as aproximately correct. In a typical boiler barrel for main line loco the tubes and flues take up aprox 1/3rd of the volume, In the boilers I measured the water space around the firebox aproximately equals this volumne, therefore the total volume of only the barrel portion of the boiler will be round about correct.

One of the most serious problems OR faces in accurately specifing locos is finding the required data, a lot of it is simply not availible so in the end some type of guessing will need to be done. Such rules of thumb as this one will likely in a lot of cases be the only way such information will be found.

Lindsay

#6

Posted 21 March 2012 - 02:43 PM

Details directly,

Lindsay

#7

Posted 22 March 2012 - 03:56 PM

Walter Conklin, on 21 March 2012 - 02:45 PM, said:

Walter Conklin, on 21 March 2012 - 02:45 PM, said:

Just curious - what version of OR are you using?

Thank you.

The latest version currently on the OR webs site V0.7 something or other, can not give the complete version number as I am running LInux at the moment.

I have though 3 (I think) other versions installed which I use for comparison purposes. Curiously the current version give problems on one particular steamer and this is taking considerable time to track down why. It is definitely something in the eng file but there is no obvious reason for it to miss behave.

I am currently having a short(ish) break from OR as being accused of making random changes in the eng files has unfortunately annoyed my badly.

Lindsay

#8

Posted 24 March 2012 - 04:04 AM

Cheers Bazza

#9

Posted 24 March 2012 - 10:14 AM

captain_bazza, on 24 March 2012 - 04:04 AM, said:

captain_bazza, on 24 March 2012 - 04:04 AM, said:

Cheers Bazza

I have no idea what OR's definition of BoilerVolume is but the definition I am working on here is the total internel space of the boiler. If you use that AND use a boiler output figure close to reality the system works OK (on my system any way). There is a problem here as far as i can figure out OR currently does not allow one to change the boiler response time and if one sets the boiler output even fractionally low the pressure drops way to quickly.I have found it is required to set the boiler output slightly above reality. Boiler tests for H220 shows the out put as 37,500 lbs per hour, I found one had to set this in OR as 40,000 lbs per hour to make the loco driveable. Mind this is a long way better than the 60,000 lbs per hour required before.

Lindsay

#10

Posted 24 March 2012 - 02:53 PM

Cheers Bazza

Log In

Log In Register Now!

Register Now! Help

Help