WIshes for Steam Locomotive advancement

#81

Posted 24 January 2021 - 11:31 AM

Brandon

Here is what it says about Safety Valves!

SAFETY VALVES

Number and Capacity— Every boiler shall be equipped with at least two safety valves, the capacity of which shall be sufficient to prevent, under any con- ditions of service, an accumulation of pressure more than 5 per cent, above the allowed steam pressure.

Setting of Safety Valves— Safety valves shall be set to pop at pressures not exceeding 6 pounds above the working steam pressure. When setting safety valves two steam gages shall be used, one of which must be so located that it will be in full view of the person engaged in setting such valves; and if the pressure indicated by the gages varies more than 3 pounds they shall be removed from the boiler, tested, and corrected before the safety valves are set. Gages shall in all cases be tested immediately before the safety valves are set or any change made in the setting. When setting safety valves the water level in the boil - shall not be above the highest gage cock.

Brandon

https://archive.org/...age/n4/mode/2up

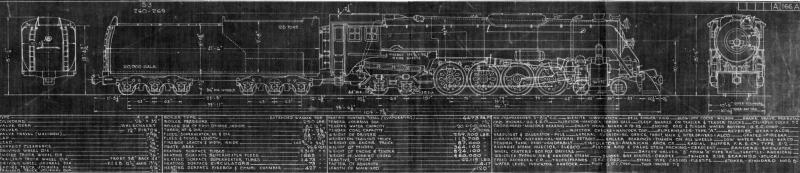

Milwaukee Road S3 class 4-8-4 260-269

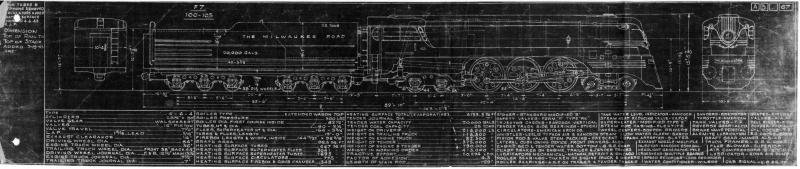

Milwaukee Road F7 class 4-6-4 100-105

#82

Posted 25 January 2021 - 12:58 AM

darwins, on 24 January 2021 - 07:15 AM, said:

darwins, on 24 January 2021 - 07:15 AM, said:

darwins, on 24 January 2021 - 07:15 AM, said:

darwins, on 24 January 2021 - 07:15 AM, said:

darwins, on 24 January 2021 - 07:15 AM, said:

darwins, on 24 January 2021 - 07:15 AM, said:

darwins, on 24 January 2021 - 07:15 AM, said:

darwins, on 24 January 2021 - 07:15 AM, said:

The high burn rate suggests that the fire is still burning at a "high level" which would be contributing to the high input heat. Over time it reduces, and so does the Heat input. So in the first screenshot the fire is more then "covering" the heat loss due to the safety valves. As it decreases the safety valves have more of an effect on the high boiler pressure.

#83

Posted 25 January 2021 - 01:15 AM

Quote

The worrying thing at this point is that Heat In exceeds Heat Out and Stored Heat is continuing to rise. (Suggesting that pressure should also be rising still.) We should expect at this point that heat in and heat out would be equal and that the pressure would remain constant - perhaps somewhere between 225 and 228 psi - until heat in falls below heat out.Without a defined test case, I am not sure how the locomotive has been driven and fired, however I would offer the following comment.

The high burn rate suggests that the fire is still burning at a "high level" which would be contributing to the high input heat. Over time it reduces, and so does the Heat input. So in the first screenshot the fire is more then "covering" the heat loss due to the safety valves. As it decreases the safety valves have more of an effect on the high boiler pressure.

The significant point at that time is not the high heat input, which you correctly state is due to having arrived at that point with a large, hot fire. The issue of concern is the apparently low value of the heat output compared to the following two frames. The impact of pop safety valves opening should be instant and very large - there should not be a delay as the rate of heat loss (steam loss) increases.

#84

Posted 25 January 2021 - 11:21 AM

Because of the system of piping the steam must travel to in order to get from the boiler to the cylinders, there is always an inherent delay from the moment the engineer changes the throttle position until those changes are reflected in the cylinders, whereas in OR, the change is near-instant.

In the case of a saturated locomotive, the steam must pass through the throttle valve, dry pipe and branch pipes, and past the valves before it pushes the piston. Depending upon the length of the boiler, the delay may be anywhere between 3-5 seconds before the locomotive starts to move. The same thing happens when the engineer closes the throttle--the steam already in the piping must first exit the dry pipe, the branch pipes, the cylinders and be exhausted out the atmosphere, and it takes about 3-5 seconds (depending on speed) before the cylinders are completely empty.

In the case of a superheated locomotive with a dome throttle, the delay is significantly longer--perhaps 10 seconds or so. This is because after passing through the dry pipe, the steam must pass through the superheater header and each of the superheater elements before reaching the branch pipes. It is for this reason that dome throttles on superheated engines were phased out in favor of front-end throttles. When a locomotive has a front-end throttle, the dry pipe and superheater are always filled with steam, and when the engineer opens the throttle, steam has to only travel through the branch pipes to the cylinders, and thus there is a wait of only about 2-3 seconds before the engine moves.

...That is a very crude explanation, but you can see the point I'm trying to make.

#85

Posted 25 January 2021 - 09:48 PM

darwins, on 25 January 2021 - 01:15 AM, said:

darwins, on 25 January 2021 - 01:15 AM, said:

In the first screenshot, the injectors are not operating. In the following two screenshots, the injectors have turned on to replenish the water exhausted out of the steam relief valves. This explains the apparent increase in Heat Out between the first and second screenshot.

So as far as I can see the safety valves seem to be working "correctly".

In the steam model heat is stored in the boiler, (ie added or subtracted), so whilever Heat In is above Heat Out then the pressure will increase.

The issue is that in the first screenshot the fire is still exceeding the heat output of the safety valves (hence addition of heat to boiler), and hence pressure drop will not occur. Which appears to be the case.

In the second screenshot, the fire heat (In) has dropped, and the injectors (Out) have switched on to increase the difference between to two (hence subtraction of heat from the boiler), so we now see the ability for the pressure to decrease. Again this appears to be the case with screenshots 2 and 3.

In real life I would suspect that it would not be good operational practice to stop a locomotive with a "raging" fire, and maintain that fire whilst stopped. I think that this is the issue that is preventing the safety valves from initially "doing their job".

In my opinion a more interesting aspect to investigate would be how the fire heat changes as the locomotive changes speed and becomes stationary, and the impact of the draught, blowers and dampers on the fire heat. How does the driver manage the fire so that its heat has dropped as the locomotive stops?

As suggested earlier, the Manual firing mode has never been fully tested to my understanding, so it may require some adjustments to work more effectively.

The AI fireman is a different story.

#86

Posted 25 January 2021 - 10:41 PM

Quote

Definitely all those things are interesting. It would be good to take one at a time. The safety valves really need to be fixed first - manual firing with coal is a total disaster when they routinely drop your boiler pressure by 40, 50, 60 or 70 psi rather than the 5 or 10 psi that happens in real life.

The two things here are

(1) if safety valves allowed more heat in than heat out - even with a raging fire - then pressure would continue to increase after the valves have lifted and the boiler would eventually explode - this does not happen and cannot be allowed to happen - in this situation I would expect to see heat out = heat in - the safety valves should remain open until heat in has been reduced - the question then becomes are the safety valves big enough for the engine

Quote

(2) when the safety valves close again there should be extra ongoing further drop in pressure other that that calculated from the balance of heat in and heat out - if you have put both injectors on full then heat out might well be greater than heat in - but more often as our various firemen have described the pressure will start to creep up again (because heat in is greater than heat out). As part of working on safety valves I was hoping to also look at different safety valves working at different pressures and at having spring safety valves as an alternative to pop safety valves. You may decide that those are things that need to come later. I will make a suggestion, in a new thread for a basic oil fired model that could be used to test these.

#87

Posted 26 January 2021 - 04:07 AM

#88

Posted 26 January 2021 - 07:32 AM

I probably have a long way to go with that so any help in making equations clear would be good.

The safety valve capacity is given as 32351 lb/h of steam which at 225 psi corresponds to 7441 Btu/s.

By default OR gives me 2x 2.5 in safety valves - I don't have the actual figure for this loco, but a design of similar size had 2x 3in Ross 'pop' safety valves.

That value seems good for this boiler - I would estimate the maximum possible evaporation to be 28492 lb/h which corresponds to 6553 Btu/s.

That should be the maximum rate at which water could be evaporated at 225 psi. The ORTS evaporation parameter is set to a lower value to represent the front end limit.

ORTSBoilerEvaporationRate ( 12.5 ) Comment ( Front end limit for single chimney Jubilee is 20760 lb/hr )

So the figure of 22313 lb/h for actual evaporation (or 5132 Btu/s) seems reasonable.

It also corresponds to the predicted evaporation from the burn rate curve, the burn rate at that time being 3028 lb/h.

ORTSBurnRate( 0 6 4752 590 9107 1180 13066 1770 16628 2360 19794 2950 22563 3540 24963 4130 26912 4720 28492 5310 29675 5900 )

So why the difference between 7441 Btu/s and 5132 Btu/s?

The amount of energy going into the boiler appears to be greater than the boiler might be expected to absorb.

#89

Posted 26 January 2021 - 08:23 AM

From observation in manual firing Boiler pressure continues to rise when safety valves are open. Also BP rises even when heat input is small, then suddenly decreases. Dampers have little effect. A kind of hysteresis loop is present

I can not read code, but it seems to be as if there is a false delay in boiler response, additionally coded on to the delay already present due to the reseve capacity of the boiler.

It is nearly impossible to control manual firing in ORTS. Yet a real fireman would have no trouble.

A group of us discussed this by PM. Unfortunately no agreement was reached. If the dampers had a much greater effect on burn rate, then control of boiler pressure would be possible. Maybe not strictly correct, but more effective dampers would enable controlled manual firing, without a total rebuild of the OR code.

Rick

#90

Posted 26 January 2021 - 08:24 AM

Another thought I had but this is for Sound. We have the Blowdown feature now but no sound can be admitted from it when you push the button.

Would really like to see this fixed eventually.

A few more thoughts is cylinder cock sound and smoke animation for multiple steam locomotives on a train and multiple whistles!

I was thinking Alt and spacebar.

If you wanted to blow a different locomotive then the lead just click on F9 and the locomotive you want to blow.

They also used this as a form of communication between the crews before Radios.

As I have stated previously that many excursion locomotives over here have multiple horns and whistles on them as well!

Brandon

Log In

Log In Register Now!

Register Now! Help

Help