Dynamic Brake Delay Time Need new ORTS parameter?

#31

Posted 22 July 2021 - 10:07 PM

#32

Posted 23 July 2021 - 06:30 AM

engineersteve, on 22 July 2021 - 10:07 PM, said:

Important point...something I had not even considered...slack ( and I love challenging undulating routes ) especially since accurate slack modeling is beginning to be implemented.

#33

Posted 23 July 2021 - 03:15 PM

Weter, on 23 July 2021 - 08:53 AM, said:

I thought, alternator is AC generator...

At the rest - right and quite simple explanation. I concur, but owe to add, that relays, and more it is applicable to drum- or finger-type group switchers, are demanding some time for switching action itself; furthermore, if scheme's logic considers that should be performed in sequence. Even if AC disappears virtually instantly, thanking to inductivity, contact switching still requires some time. But modern electronic power controllers (contact-less switching), based on controlled semiconductors switch cirquits in percents of seconds-maybe you meant thAt case.

@Steve

Right. Significant in-train forces are adle to push empty car(s) out of the train, so we have to be careful.

"Nature-list of train" document helps to realize, what train is coupled to your locomotive(s).

You said "her"? Are women at USA allowed to work as a train drivers? I wonder.

Yes all railroads in USA have female engineers. Personally I have known 5 when I was working. The engine facilities have came a long way since the steam days.

#34

Posted 23 July 2021 - 03:18 PM

engineersteve, on 22 July 2021 - 10:07 PM, said:

Hey Steve, that is a big part of yard master training as well as train handling - train marshalling. Right?

Mike

#35

Posted 23 July 2021 - 03:28 PM

Weter, on 23 July 2021 - 08:53 AM, said:

I thought, alternator is AC generator...

At the rest - right and quite simple explanation. I concur, but owe to add, that relays, and more it is applicable to drum- or finger-type group switchers, are demanding some time for switching action itself; furthermore, if scheme's logic considers that should be performed in sequence. Even if AC disappears virtually instantly, thanking to inductivity, contact switching still requires some time. But modern electronic power controllers (contact-less switching), based on controlled semiconductors switch cirquits in percents of seconds-maybe you meant thAt case.

@Steve

Right. Significant in-train forces are adle to push empty car(s) out of the train, so we have to be careful.

"Nature-list of train" document helps to realize, what train is coupled to your locomotive(s).

You said "her"? Are women at USA allowed to work as a train drivers? I wonder.

Hey Weter, CN hired their first "brakette" around 1973-74. Later on when I trained on the head end, I had Sharon as my engineer. "engineperson"

#36

Posted 23 July 2021 - 04:39 PM

I removed the delay entirely, but this presents a related problem: SET UP is not a discrete handle position that we can specify without actually moving the handle into the dynamic braking range. I tried making it a notch at zero braking effort, but this doesn't actually work, you just end up skipping right over it.

Apologies if these last two items are off-topic, but I have been thinking about them for a while and they are related.

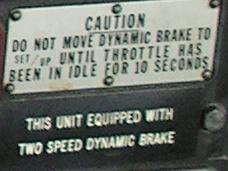

3D cabs also have a problem where any animated child of an animated parent will animate with the parent (e.g. the wipers on the cab doors will animate when the cab doors open instead of when the wipers move), so I suspect there is no way to animate the early combined throttle/dynamic braking handle in an accurate way. Combined controls don't cut it, I'm afraid - one wrong keystroke and instead of being in idle you're in set up. It's not a detent; it's a hard stop and a switch that needs to be thrown before the handle can be moved:

https://youtu.be/8_V1m7Bf7Cw?t=89

Notice the lever is notched in throttle mode and not in dynamic braking mode. The most logical way to do this is to have the throttle lever animated as the dynamic brake handle, parented to a dummy animated as the throttle (or vice-versa). I do not believe that this is possible with the current parent/child animation problem. Another problem with using a combined control setup is that the throttle requires 8 frames, while dynamic braking requires at least 100 to have smooth movement. It's just an annoyance that could be circumvented with the ability to have parents and children animate separately (after all, this works for trucks and wheels!).

Notice also that the engine powers up in dynamic braking. The fan on the top of the locomotive is only good for cooling the resistor grids. The traction motors need to have heat dissipated as well, and this takes place through the traction motor blowers, which are directly tied to engine RPM (it's what lives in the hump on the left side of most EMD locomotives). We should have a parameter to bump up the engine RPM to a set point when a certain amperage threshold is crossed in dynamic braking. The amperage parameter for the engine power up is necessary because the EMD Dash-2 line introduced two-speed dynamic brakes, where the engine stays idle until ~700 amps or so:

https://youtu.be/Tyo2EaHMmfw?t=313

#37

Posted 23 July 2021 - 06:03 PM

#38

Posted 23 July 2021 - 06:14 PM

The second video is the standardized control stand with separate handles.

#39

Posted 23 July 2021 - 06:27 PM

engineersteve, on 23 July 2021 - 06:14 PM, said:

The second video is the standardized control stand with separate handles.

Yes, I was using that video to illustrate the operation of that style of control stand, because my post was describing how we cannot currently model it accurately with the sim's available cab controls. The second video was for two purposes:

1. Contrasting the early single-handle and selector setup with the later two-handle standardized control stands which the sim can currently handle.

2. Demonstrating the difference between one-speed and two-speed dynamic brakes in the service of explaining why we should have an amperage parameter for setting engine speed in dynamic braking.

The models I build primarily fall within the transition range, so the ability to accurately set up the single-handle configuration is of particular interest to me.

#40

Posted 24 July 2021 - 04:49 AM

Well, during WWII, there was number of steam female-engineers; after it became strictly male profession. With very rare exceptions.

Last years, with microprocessor controls, the doors might be open for girls, but I didn't hear anything yet.

I think, in "progressive" states, the emancipation was a motive. And it's not bad in this case.

Log In

Log In Register Now!

Register Now! Help

Help