Hi Folks,

Are feed water heaters modeled in ORTS and if so - which injector would they be associated with... I don't recall seeing any values in the ENG files associated with them...

Regards,

Scott

Steam - Feed Water Heater ?

#2

Posted 25 January 2015 - 04:11 PM

Hi Folks,

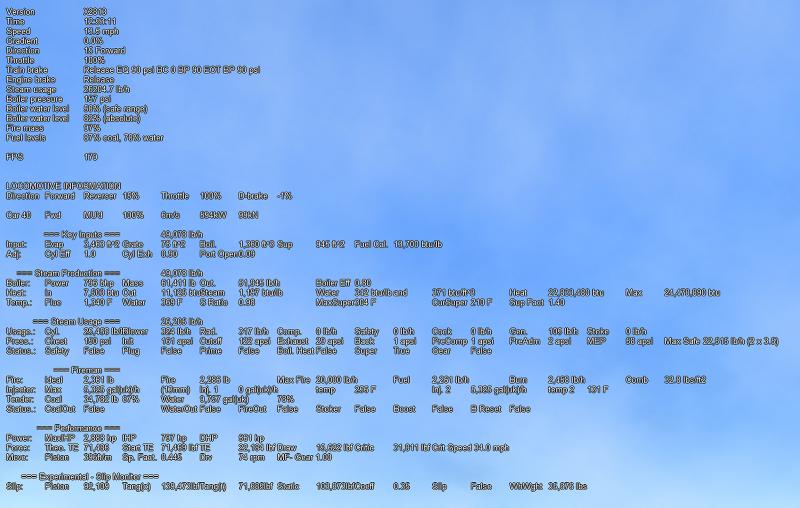

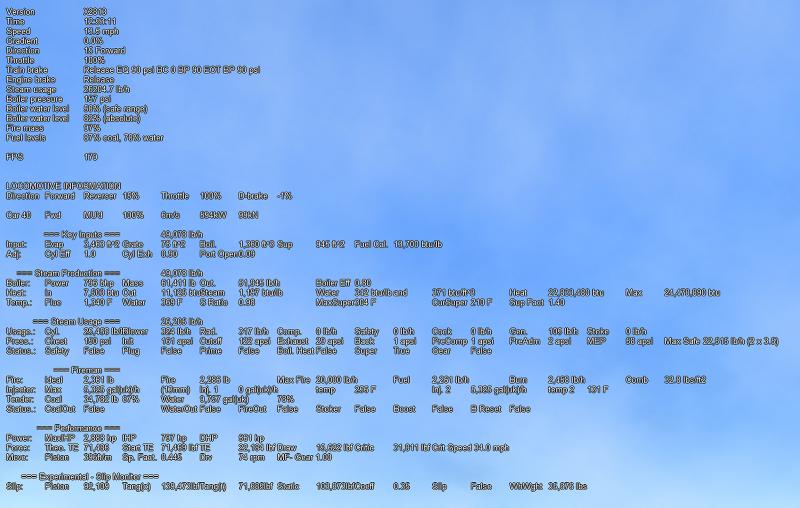

A little more information - I'm trying to hand fire - and I'm having great difficulty keeping my boiler pressure up... By the Steam HUD attached - it seems as if I am making way more steam than I'm using - but - that surplus steam doesn't seem to be making boiler pressure increase... I turned off the injectors - I have the Reverser pretty close to cut off - and - still I can't seem to recover the boiler pressure - max 220 lbs... Any idea on my screenshot on what I am doing wrong ???

Regards,

Scott

A little more information - I'm trying to hand fire - and I'm having great difficulty keeping my boiler pressure up... By the Steam HUD attached - it seems as if I am making way more steam than I'm using - but - that surplus steam doesn't seem to be making boiler pressure increase... I turned off the injectors - I have the Reverser pretty close to cut off - and - still I can't seem to recover the boiler pressure - max 220 lbs... Any idea on my screenshot on what I am doing wrong ???

Regards,

Scott

#3

Posted 25 January 2015 - 05:13 PM

Try an earlier version , I am getting a simliar thing from the 23rd Jan release the previous release tried from a week or so back worked OK.

There appears to be some change in the steam code which has changed it a good bit.

LIndsay

There appears to be some change in the steam code which has changed it a good bit.

LIndsay

#4

Posted 25 January 2015 - 05:38 PM

What happens if you go zipping along the main w/ mo cars? Do you build your steam pressure back up?

Given what you show, above, I'd stop moving and let the pressure return to max before I tried anything again.

Given what you show, above, I'd stop moving and let the pressure return to max before I tried anything again.

#5

Posted 25 January 2015 - 06:45 PM

Bad coal! http://www.elvastower.com/forums/public/style_emoticons/default/girl_devil.gif

CB.

CB.

#6

Posted 25 January 2015 - 06:56 PM

Hoggers call that "Blowing Up" ( Stopping to Build up Steam ) I see your Throttle is at 100% Back That Off a Tad ( Half way or a little more ) use the Johnson Bar ( reverser ) to Regulate. Try that as I think you are at Maximum Exhaust/Steam Rate at 100%. Real Life Scenario a Good Engineer will "Set" His Throttle and "Regulate" with the Johnson Bar because it made Firing the Locomotive Easier. Some Engineers that did not like their Assigned Fireman ( Student/Bad Reputation ) would Jam on the Throttle all the Time Devouring Steam Coal and Water, and Nearly Exhausting the Fireman who has Two Jobs Really, Firing the Engine and by Railroad Rules Jumping into the Left Seat on all Left Curves to Watch for Obstructions etc. as the Engineer can't see on that side! I have Read of Fireman Laying on the Cab Floor at the End of a Pay Trip because an Engineer made him work Triple Hard.

#7

Posted 25 January 2015 - 09:11 PM

FWIW I do have a Feedwater Operation Manual on hand and so if there is anything inadequate about the way OR handles the feedwater I can look up the topic in the manual and report what I find.

#8

Posted 26 January 2015 - 02:06 AM

Feedwater heater is not modelled yet in OR steam code. What we have is a basic engine still undergoing tweaks some of which do not work as intended sometimes.

I don't think hand firing will work on large US type steam engines until we have proper steam stoker code. The burn rate on the grate is far too high for one man and a shovel. You should be able to hand fire the smaller engines up to light pacific size.

Currently, Otto the auto is the only fireman who can keep up with demand on the large engines.

I don't think hand firing will work on large US type steam engines until we have proper steam stoker code. The burn rate on the grate is far too high for one man and a shovel. You should be able to hand fire the smaller engines up to light pacific size.

Currently, Otto the auto is the only fireman who can keep up with demand on the large engines.

#9

Posted 26 January 2015 - 04:06 AM

Hi Folks,

Thanks for the responses and greatly appreciate the feedback... I do hand fire fairly regularly - as Lindsay mentioned - I think the problem might be due to some recent code changes - I have noted some significant differences in running steam in ORTS lately - and - I understand it's a work in progress...

I was going to ask about the "Stoker" on the HUD - as it always seems to be set to false - I didn't see any way to set it to "True"... That said - currently - I do seem able to increase the "Firing Rate" sufficiently to keep the "Fire" at 100% - not sure if that's due to an "Eng" file setting or how a mechanical stoker would change that ???

As posted above - I had read an article that agrees - stated that the engineer would simply leave the regulator open - and - use the Reverser for speed/steam control - which is typically how I run in ORTS...

Even if I stop and turn the blower on - lately - it seems extremely difficult to build up a head of steam...

Thanks ORTS Team for all you do...

:D

OBTW - I looked closely at the screenshot I posted above and I noted the temp of the water being injected by "Injector 1" seems to be more than 100 degrees hotter than the water injected by "Injector 2"... So it must assume a feed water heater - no ??? I just can't find any corresponding settings in the ENG file to have any control over that feature... Not all locomotives have feed water heaters so there should be some means to disable that...

Regards,

Scott

Thanks for the responses and greatly appreciate the feedback... I do hand fire fairly regularly - as Lindsay mentioned - I think the problem might be due to some recent code changes - I have noted some significant differences in running steam in ORTS lately - and - I understand it's a work in progress...

I was going to ask about the "Stoker" on the HUD - as it always seems to be set to false - I didn't see any way to set it to "True"... That said - currently - I do seem able to increase the "Firing Rate" sufficiently to keep the "Fire" at 100% - not sure if that's due to an "Eng" file setting or how a mechanical stoker would change that ???

As posted above - I had read an article that agrees - stated that the engineer would simply leave the regulator open - and - use the Reverser for speed/steam control - which is typically how I run in ORTS...

Even if I stop and turn the blower on - lately - it seems extremely difficult to build up a head of steam...

Thanks ORTS Team for all you do...

:D

OBTW - I looked closely at the screenshot I posted above and I noted the temp of the water being injected by "Injector 1" seems to be more than 100 degrees hotter than the water injected by "Injector 2"... So it must assume a feed water heater - no ??? I just can't find any corresponding settings in the ENG file to have any control over that feature... Not all locomotives have feed water heaters so there should be some means to disable that...

Regards,

Scott

#10

Posted 26 January 2015 - 11:09 AM

In the screenshot, injector 1 is not passing any water to the boiler, and should be showing 0 degrees. Injector 2 is pushing water in, and that temp looks to be correct. Feedwater heaters usually have a pump to push the hot water into the boiler, although there was also an injector made that could handle hot water without failing and was used instead of the pump. However, none of the physics involved in the feedwater heater have been modelled yet, likewise the mechanical stoker, although the auto fireman performs like one.

Back to the fire and burnrate. There was a recent code change that introduced a change to an old parameter that was no longer working properly. ORTSBurnRate is the name and now has a default curve attached to it

ORTSBurnRate( 0.0 10.0 9000.0 1000.0 14500.0 2000.0 21000.0 3000.0 26400.0 4000.0 30800.0 5000.0 34400.0 6000.0 37500.0 7000.0 40200.0 8000.0 42800.0 9000.0 45200.0 10000.0 47800.0 11000.0 ) which works quite well in auto mode.

These figures are in x,y pairs where x = Steam evaporation rate in lb/hr and y = Dry coal fired rate in lbs/hr. If you run in auto mode and watch the locomotive information page you can see this working. If you know the amount of fuel used for a given amount of steam produced by a locomotive boiler, you can make your own. However, get the curve wrong and you will either run out of steam, or burn too much fuel. When I did my first one I got it wrong and was losing boiler pressure quite fast.

Back to the fire and burnrate. There was a recent code change that introduced a change to an old parameter that was no longer working properly. ORTSBurnRate is the name and now has a default curve attached to it

ORTSBurnRate( 0.0 10.0 9000.0 1000.0 14500.0 2000.0 21000.0 3000.0 26400.0 4000.0 30800.0 5000.0 34400.0 6000.0 37500.0 7000.0 40200.0 8000.0 42800.0 9000.0 45200.0 10000.0 47800.0 11000.0 ) which works quite well in auto mode.

These figures are in x,y pairs where x = Steam evaporation rate in lb/hr and y = Dry coal fired rate in lbs/hr. If you run in auto mode and watch the locomotive information page you can see this working. If you know the amount of fuel used for a given amount of steam produced by a locomotive boiler, you can make your own. However, get the curve wrong and you will either run out of steam, or burn too much fuel. When I did my first one I got it wrong and was losing boiler pressure quite fast.

Log In

Log In Register Now!

Register Now! Help

Help