steamer_ctn, on 03 May 2014 - 05:36 PM, said:

steamer_ctn, on 03 May 2014 - 05:36 PM, said:

I have updated the friction code in #2209, which should address the issues raised above with wagons of the same type not having consistent friction values, etc.

Cheers

Hi

Thanks peter for the update.

Its working now. All wagon with MSTS values gets OR 0,9 settings now.

Now i can drive long trains again without stalling the train in starting moment.

Forum title is maybe it is a bug = yes it was.

We found it and peter fix it.

Now it will works for

all wagons and not just for some wagons that it was before.

It was a pretty messy process to find the error on the friction on wagons and engines. (70 topics)

At first I did not know how the programmer wanted to friction would work.

It took two months before I realized that if you had just MSTS values, it would

act as the OR of 0.9. (no high start friction)

The only thing I felt that this can,t be right.

In the beginning I thought you wanted to have friction bearings (high start fricion) on all wagons,

Because in practice, it did so. and several said it was quite right.

So that's why I and many said we wanted Low as default for a long time.

Now, I do not think the discussion is so interesting again.

It was when I had only 10 wagons that they saw the error in F5 Hud.

When you have 100 wagons may be just information (F5 Hud) on wagon 1, 10, 20, 30 and beyond.

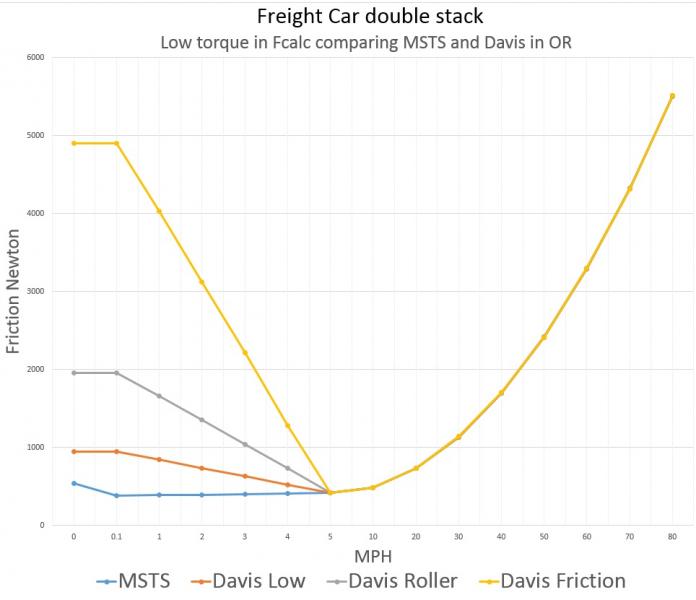

But we have also on the way fixed ( Low ) Thats are new wagons roller bearings values. (lower starting friction)

It would help if the programmer could talk about how he wants the change he has made to work in practice. Much easier to debug.

Possible that the information was there but I have not found it.

Will test the wagons later to compare old and new.

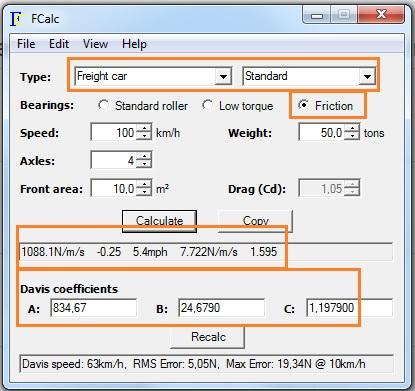

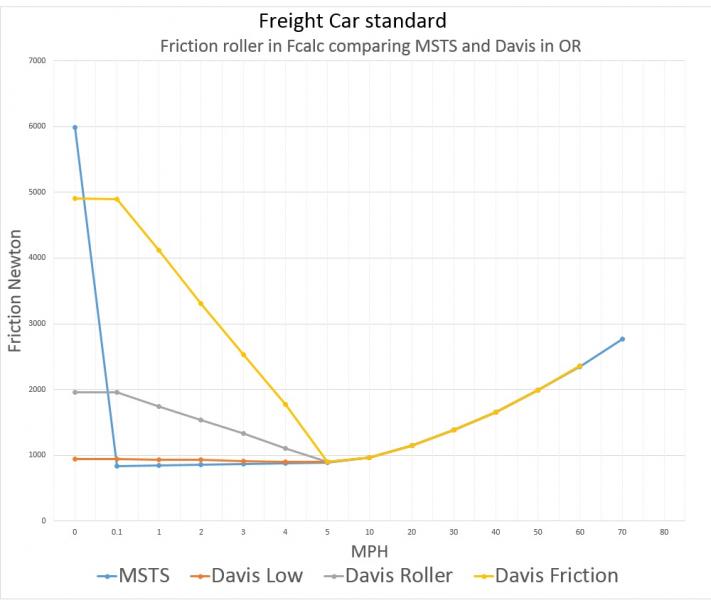

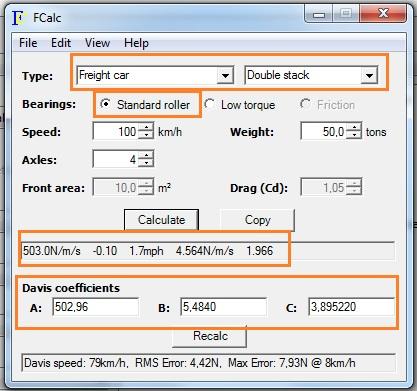

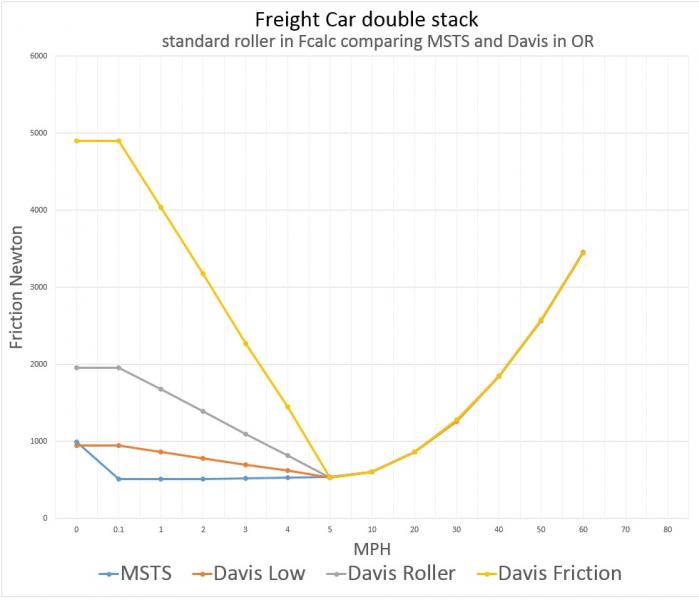

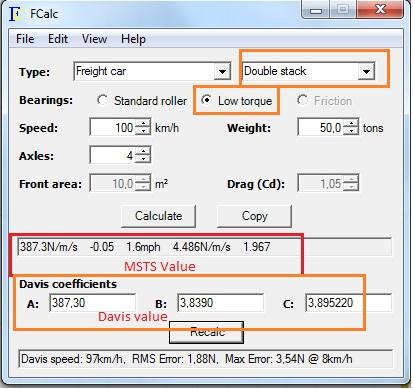

MSTS old friction values (Fcalc) (OR 0.9 settings) Ex Friction (503N/m/s -0.10 1.5mph 4.945N/m/s 1.939)

OR New friction values (Davis)

Ex.

ORTSDavis_A (500.165)

ORTSDavis_B (2.49802)

ORTSDavis_C (0.045)

ORTSBearingType ( Friction or Roller or Low )

Jorgen Naslund

jorgen, on 27 April 2014 - 06:33 AM, said:

jorgen, on 27 April 2014 - 06:33 AM, said:

Log In

Log In Register Now!

Register Now! Help

Help