cjakeman, on 02 June 2013 - 06:10 AM, said:

cjakeman, on 02 June 2013 - 06:10 AM, said:

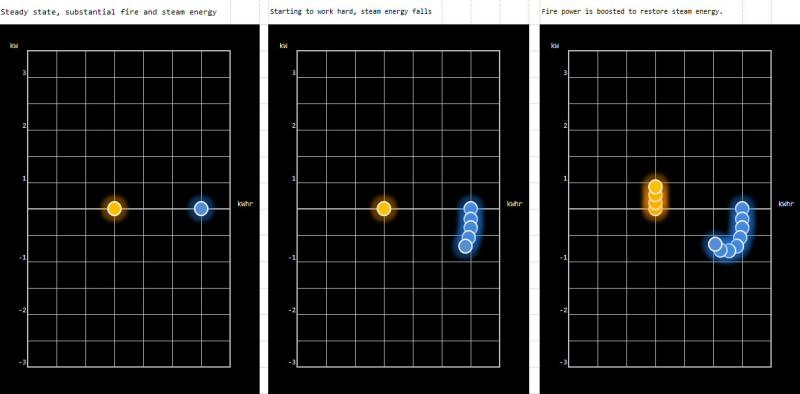

I wonder if anyone will comment on the importance (or not) of managing the fire as well as the boiler? We have two dynamic systems here linked by a time delay which is probably why driving steam is harder than driving modern traction.

Don't you have to build up the fire right now because the route will make an extra demand for steam in a few minutes time? And at the end of the route, don't you cease firing early leaving just enough steam to reach your destination?

I can share a few observations about this, though they are based off of running a steam tractor, the behaviors will be very similar :) Since we fire with coal my observations will be based on coal being used as fuel...

Management of the fire with coal is indeed very critical and nothing can substitute for practice and experience. In a nutshell, you always have to be thinking several minutes in advance for what you'll be doing since coal fires don't respond instantly. If you anticipate that your steam demand will be going up (increased speed or load in the near future) that's the time to start adding or increasing the rate of coal added to the fire so it will have a chance to get lit and burning before the increased load occurs. The opposite is true when you anticipate a lighter load or slower speed in the near future - decrease the rate of adding coal or stop adding giving a chance for the mass of the fire to decrease before the lighter load arrives. Management of the dampers figures into all of this too, as you can use them as a kind of regulator for the fire. With increasing loads coming in the future, open the dampers up the needed amount to give the fire more air. If a reduction in load or stop is anticipated, closing the dampers in advance will help the fire to begin to cool down a bit so you don't have a pressure spike when the steam demand drops, or stops.

Then add to that water management... Of course the golden rule that can't be violated is to let the water get too low in the boiler. Likewise too much is a problem that can cause carryover into the cylinders (potentially damaging the cylinders or running gear) and making the engine hard to fire. So there's always a balancing act going on. Ideally if everything is working at a steady state you can adjust the addition of water to match the rate of consumption and fire according to demand. Or you can have a balancing act between when you add water and when you add fuel. My experience on the steam tractor is that it usually works pretty well to have a sort of rhythm... When the stack becomes clear loss of boiler pressure is right around the corner, so add coal. At this time water isn't being added because it has a chilling effect on the boiler. Of course the degree to which this varies depends on whether you're adding water with an injector which heats the water to some extent, or with a pump and feedwater heater. When the fresh fuel takes off pressure will start to tend to climb - then you can freely add water to the boiler and still maintain pressure. Then repeat the cycle, always trying to avoid a situation where you need to add water and add fuel at the same time, both of which have an initial chilling effect and possible drop in pressure.

Beyond all that, just managing the fire bed is an art... The coal never burns completely even over the entire grate surface. Maybe the front half of the firebox consumes more than the rear on average, or perhaps the sides consume more than the middle or front corners, etc. In general the key is to keep the fire evenly spread in spite of the varying burn rates across the total area. The main thing to avoid is letting an area get too thin so that cold air is able to make it through the firebed - this can drop your pressure in a hurry if a thin spot develops.

It really is an immersive experience, always trying to anticipate the future, balancing water vs. fuel needs at any given moment, listening to the sound of the engine and how hard it's working, observing the color of the smoke as an indication of whether the fire is "rich" or "lean", and knowing not only how much coal to add to the fire but just as importantly where to add it. ;)

This is why I've never been able to get into the virtual firing of steamers in the sim... no sim will ever be able to truly replicate all of this. But I do agree with copperpen that it would be nice to be able to operate in the sim in either "engineer" or "fireman" modes, rather than having to try to do both at once which isn't prototypical. As for any kind of aids to assist in managing the boiler I think there's really only 3 needed as long as the physics of the engine are right - color of the smoke, pressure gauge, and water glass :)

Log In

Log In Register Now!

Register Now! Help

Help