Jean-Paul, on 23 January 2023 - 12:11 PM, said:

Jean-Paul, on 23 January 2023 - 12:11 PM, said:

Here are the files :

Jean-Paul, on 22 January 2023 - 10:38 AM, said:

Jean-Paul, on 22 January 2023 - 10:38 AM, said:

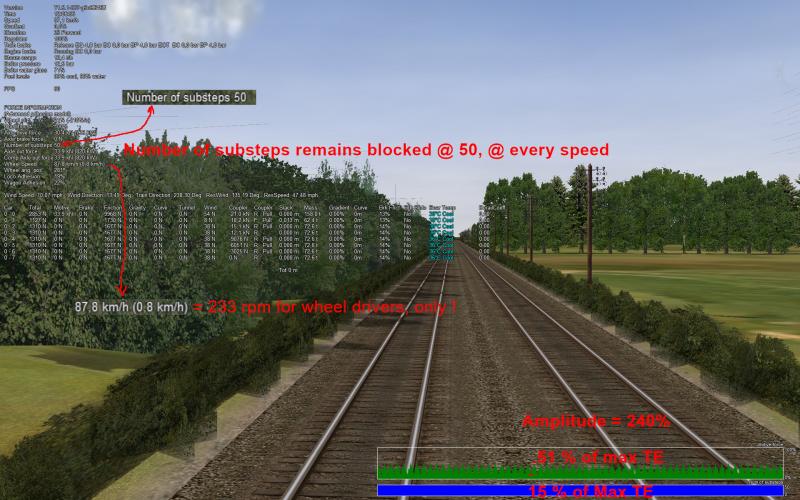

tractive effort is perpetually oscillating,

I am a little bit confused as both of your screen shots show the Power In/Out rather then tractive effort.

Tractive effort (force) is found on the Forces Information HuD.

I have run a test with my test model at 100% throttle and 40% cutoff, with as set Drive wheel weight and also with weight increased to 2 x the actual. Both runs seem to show a similar tractive effort.

Also looking at the maximum and minimum values of "Axle Drive Force" at various speeds, which represents the input tractive effort of the locomotive, this appears to be within the same sort of bounds as shown in the graphs on the stock page displayed near the locomotive. So I can't see where TE is oscillating outside of the expected bounds.

So at the moment I can't see any issues with the TE calculations. I can't comment on the Power calculations apart from saying that I am unaware of any issues with them at the moment.

If I get time I will look at your ENG/WAG files and the power calculations when I get some time, however I will be away for a few weeks within the next few days, so it may not be for a while.

If you wish you can repeat my tests with my test model, and if you identify any issues using it I might be able to have a quick look at it.

Log In

Log In Register Now!

Register Now! Help

Help