WIshes for Steam Locomotive advancement

#21

Posted 18 January 2021 - 01:23 PM

Brandon

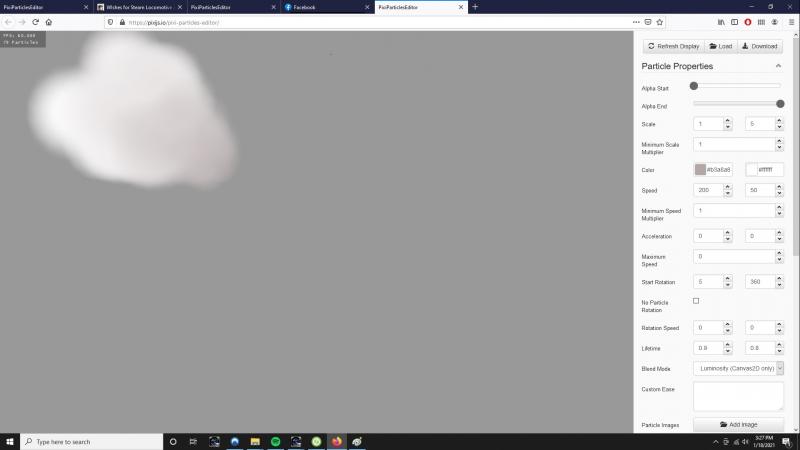

https://pixijs.io/pi...ticles-editor/#

Here is the particles that I created. Not sure if this coding can be implemented into the game but just as a shot here is the coding for it.

{

"alpha": {

"start": 0,

"end": 1

},

"scale": {

"start": 1,

"end": 5,

"minimumScaleMultiplier": 1

},

"color": {

"start": "#b3a8a8",

"end": "#ffffff"

},

"speed": {

"start": 100,

"end": 200,

"minimumSpeedMultiplier": 1

},

"acceleration": {

"x": 0,

"y": 0

},

"maxSpeed": 200,

"startRotation": {

"min": 1,

"max": 360

},

"noRotation": false,

"rotationSpeed": {

"min": 0,

"max": 0

},

"lifetime": {

"min": 0.9,

"max": 0.8

},

"blendMode": "luminosity",

"frequency": 0.011,

"emitterLifetime": -1,

"maxParticles": 500,

"pos": {

"x": 0,

"y": 0

},

"addAtBack": false,

"spawnType": "circle",

"spawnCircle": {

"x": 0,

"y": 0,

"r": 0

}

}

Here is the second photos coding as well.

{

"alpha": {

"start": 0.45,

"end": 0

},

"scale": {

"start": 0.1,

"end": 1,

"minimumScaleMultiplier": 1

},

"color": {

"start": "#85888d",

"end": "#100f0c"

},

"speed": {

"start": 300,

"end": 700,

"minimumSpeedMultiplier": 1

},

"acceleration": {

"x": 0,

"y": 0

},

"maxSpeed": 0,

"startRotation": {

"min": 250,

"max": 290

},

"noRotation": false,

"rotationSpeed": {

"min": 0,

"max": 0

},

"lifetime": {

"min": 0.5,

"max": 1

},

"blendMode": "normal",

"frequency": 0.001,

"emitterLifetime": -1,

"maxParticles": 500,

"pos": {

"x": 0,

"y": 0

},

"addAtBack": true,

"spawnType": "point"

}

#22

Posted 18 January 2021 - 09:58 PM

NickonWheels, on 18 January 2021 - 04:04 AM, said:

NickonWheels, on 18 January 2021 - 04:04 AM, said:

As far as water and steam consumption are concerned, the OR model has been tested against a number of railway test reports, and OR performs within a reasonable tolerance of these test reports (including water and coal consumption).

Having OR's performance described as "just undescribeabably bad" without any supporting evidence can be very discouraging, given the effort and time put into getting the OR code to provide the most realistic steam locomotive performance possible. It is also not very helpful in identifying any potential issues.

Do you have test report information for the locomotives that you are running, and getting poor results for?

Maybe the locomotives require further tuning? A BASIC ENG file configuration will always provide a more generic outcome.

If the ENG file is not set up accurately, it could also be a case of, "garbage in = garbage out", which is a common computer problem.

ATSF3751, on 18 January 2021 - 06:35 AM, said:

ATSF3751, on 18 January 2021 - 06:35 AM, said:

That already should be possible with the current OR model, but you will need to understand the difference in operation and physics of coal vs wood burning, etc.

I recently set up a wood fired locomotive, so I know that it can work reasonably well.

ATSF3751, on 18 January 2021 - 08:32 AM, said:

ATSF3751, on 18 January 2021 - 08:32 AM, said:

The factor of adhesion (FoA) was a rule of thumb calculation (indicative) used by locomotive designers to determine whether their design was prone to slipping. OR calculates this value as a guide and displays it on the HuD.

The FoA is not a definitive point at which the locomotive will start slipping. Slipping depends upon a number of factors, such as the adhesive weight, tractive effort (which is how the FoA is determined), but it also influenced by the gearing (valve gear) of the locomotive, etc.

Open Rails uses a forces based model using the description of slipping found in this locomotive design book. This provides a more accurate determination of slippage then just using a indicative FoA value.

#23

Posted 18 January 2021 - 11:23 PM

Doing a little research this is how FoA is figured out in the US.

For any steam locomotive, the ratio of the weight on drivers divided by the Tractive Effort is called the Factor of Adhesion. It has been found that a Factor of Adhesion of around 4 is a good balance of pulling force and weight on driver.

Railroad Locomotive Type Road Number Factor of Adhesion for some American steam locomotives.

4-8-2

Erie Berk 2-8-4 3385-3404 3.63

Pere Marquette Berk 2-8-4 1216-1227 4

L&N Berk 2-8-4 1964-1969 4.1

4-6-4

C&NW Hudson 4001-4009 3.92

NYC Hudson 5445-5454 4.6

MILW F-7 Hudson 100-105 4.29

DL&W Hudson 1151-1155 4.08

4-8-4

Milw S3 260-269 4.18

Frisco Northern 4503-4514 3.92

NYC Niagara 6000's 4.4

CRIP Northern 5100-5109 4.18

N&W J 600 class 3.6

SP 4450 series 4450-4457 3.54

ATSF 2900 series 2900-2929 4.45

DL&W Pocono - 1631 class 1631-1650 3.8*

* as built

PRR 4-4-4-4 6110-6111 4.12

#24

Posted 19 January 2021 - 01:51 AM

Regarding water consumption a rather burning question is why the 'radiation' part got deleted? Every steam locomotive (or indeed any boiler) loses water over time as it gets evaporated. Older versions of ORTS had this feature though there were only two fixed values for this, which is incorrect too as this depends on the size of the boiler. This means if an engine has no mechanical stoker/generator/drainpipe etc. it also has no steam consuption and therefore no water consumption too.

#25

Posted 19 January 2021 - 03:39 AM

NickonWheels, on 19 January 2021 - 01:51 AM, said:

NickonWheels, on 19 January 2021 - 01:51 AM, said:

Regarding water consumption a rather burning question is why the 'radiation' part got deleted? Every steam locomotive (or indeed any boiler) loses water over time as it gets evaporated. Older versions of ORTS had this feature though there were only two fixed values for this, which is incorrect too as this depends on the size of the boiler. This means if an engine has no mechanical stoker/generator/drainpipe etc. it also has no steam consuption and therefore no water consumption too.

Coal consumption is directly affected by how the regulator and reverser are handled which eventually translate into pwer at the rail. Calorific value is also working correctly. Adjust the calorific value and run until the tender is empty, restart with a different figure and retest. Fuel is also consumed when at rest, if you dont see that then you have a problem with your eng file. Same with water usage at rest.

#26

Posted 19 January 2021 - 03:47 AM

ATSF3751, on 18 January 2021 - 11:23 PM, said:

ATSF3751, on 18 January 2021 - 11:23 PM, said:

Doing a little research this is how FoA is figured out in the US.

For any steam locomotive, the ratio of the weight on drivers divided by the Tractive Effort is called the Factor of Adhesion. It has been found that a Factor of Adhesion of around 4 is a good balance of pulling force and weight on driver.

That is a standard method of calculating a theoretical FoA in dry conditions with perfect rail, and as far as I am aware is the method Peter has used in the OR code. The actual implementation of that code is however far to abrupt, not allowing for the inertia of the driving wheels at slow speeds when most wheel slip happens.

#27

Posted 19 January 2021 - 03:51 AM

Quote

You are correct that if fuel calorific value is the only thing that you change in the eng file that changes are not obvious. Internal calculation does I believe use that in calculating energy input and output that should lead to power at the rail or steam used elsewhere.

To get a more convincing effect, you need to input a burn rate curve for any particular fuel being used. You may also need to adjust the Max Indicated Horse Power for different fuels. (Remember for real steam locos that calorific value was not the only consideration, different types of coal, soft, hard, large lumps, small lumps, slack - and the build of ash or clinker would all effect performance too.)

Overall I am happy that fuel consumption is in the right area. Although I have helped to run tests to confirm data, I am not convinced that it always matches burn rate curves. Part of the reason given for that is the time to reach a steady state. If you want to get some data for actual fuel consumption to compare with burn rate you will need to run some tests using a constant steaming rate - that is select a number say 20 000 lb/h steam rate then drive your train for say 20 or 30 minutes constantly adjusting the reverser to keep the steam rate as close as possible to that number. It should be possible to record that data in a log file.

Oil firing will be a different matter, unlike wood or coal there is no delay in releasing energy from the fuel so OR would need to modified to give different boiler response to oil firing.

Some work has been done on the amount of coal consumed when the locomotive is not in use. This was based around the heat lost by radiation. For most well lagged steam boilers - this is remarkably small - generally needing a coal consumption of less than 10 lb/h. (Which fits with the idea that you can leave a loco in the yard with a small fire overnight and it will not burn down too much.) You can enter parameters for the boiler surface area, proportion of boiler lagged and the thermal properties of the insulation if you want to change this.

At the moment although the burn rate can drop to very low values, the feed rate remains at a minimum 10 lb/h - which can result in increasing boiler pressure and "stored energy" if a loco is left to stand for a long period.

Quote

Do you mean radiation? If there is no steam being used how does it escape from the boiler? The only cause I can think of would be leaks. So if there are no leaks there should be no water loss as it is a closed system. You will have an equilibrium where rate of evaporation will equal rate of condensation. Excess heat will increase the pressure of the system. This would lift the safety valves - and then lose a lot of water. What happens in OR in this case is that "stored energy" continues to increase without ever lifting the safety valves unless you are in manual firing mode.

#28

Posted 19 January 2021 - 06:13 AM

Many US steamers have many of these aspects and you can not just leave a locomotive to sit overnight without using any coal or water. There is usually always a hostler on the locomotive over night. Especially on coal burning steam locomotives.

Another thing I realized the other day while running steam with diesel is that steam locomotives slip easier when a diesel is behind it and giving power as well for some reason.

Also the smaller the wheel diameter is the easier it slips too.

This should not be the case at all. I think the factor of adhesion needs to be completly separated from diesel and electric factor of adhesion as they are completely different.

You also have to cut the driver diamitor in half to get the actual diamitor! Why is that? You should be able to put in the correct diameter in and it ne right!

Brandon

#29

Posted 19 January 2021 - 07:13 AM

When a locomotive has a mechanical stoker, the stoker was only used when the locomotive was moving. The loco was generally fired by hand while idling, standing, stopping or drifting since there is limited if any demand for steam and using the stoker would be a waste of steam. When first starting from a stop, the stoker would be started no less than two minutes afterward.

In other words, the feed rate should not affect the steam usage rate within 2 minutes of starting from a stop, or while stopping, idling or drifting, since the loco will be "fired by hand".

#30

Posted 19 January 2021 - 01:35 PM

https://en.wikipedia...chanical_stoker

https://www.steamloc...nces/stoker.php

https://www.tandfonl...5.1954.10467614

https://wiki.opensou...ne_Design_Notes

http://www.railway-t...-vs-diesel.html

#31

Posted 20 January 2021 - 07:30 AM

Here we observe that the stoker is the only thing causing steam consumption. Maybe this is correct, but in reality the blower is activated when idling, something the AI fireman does not take into account (also true for safety valves)...

Here, about 10 minutes later the amount of coal in the tender is still the same, which is wrong as the water needs a constant flow of energy to stay evaporated, independent of fuel calorific values which I may have to test. I have´nt driven oil-fired steamers for a while because of this.

Regarding the burn rate curve that has no influnce upon the fuel quantity value. Also where we can get the values from?

Regarding boiler lagging; yes I tested those lines but to no avail.

#32

Posted 20 January 2021 - 07:51 AM

Standard Dupont Simplex Stoker

Duplex Stoker

Berkley Stokers (Pages 638 to 640)

Hanna Stokers

Standard Stokers (Pages 642 to 645)

Standard MB Stoker Diagram

Standard HT Stoker Diagram

Standard BK Stoker Diagram

Elvin Stoker (Pages 176 to 180)

Hanna Stoker Diagram

"Street" Stoker Diagram

1944 Suggested Unit Course in Locomotive Firing--Stokers (Pages 29 to 49)

BTW: Just to clarify what I mean by "The Stoker should not be used while idling", I have highlihgted the following quotes from the 1944 firing guide:

#33

Posted 20 January 2021 - 02:06 PM

Things in progress

- New Smoke

- Sparks/burning embers

- Steam Locomotive Per Axle Wheel Radius (many steam locomotives have different sized wheel on different trucks - sometimes on the same truck)

Future

- Chuffing/synchronized sound

- Reverser Animation

What needs to be fixed/Updated with Coding

- BTU

- Coal and Water consumption

- Stoker/Hand Fired

- Working Blower

- Factor of Adhesion

- Steam Locomotive Wheel Slip Animation Needs to be Retarded to Behave More Prototypical-

- Blow down for both sides of locomotive simultaneously

- Feed Water Heaters/injectors

- Updated Fire Modeling Physics

Eventually would like coded

- Working boosters

- Steam and smoke effected by cold or weather

- More then one whistle/Horn button

- More Light Switches to Accommodate Class Lights.

If anyone else can think of more please feel free to add.

Brandon

#34

Posted 20 January 2021 - 03:46 PM

ATSF3751, on 20 January 2021 - 02:06 PM, said:

ATSF3751, on 20 January 2021 - 02:06 PM, said:

Things in progress

- New Smoke

- Sparks/burning embers

- Steam Locomotive Per Axle Wheel Radius (many steam locomotives have different sized wheel on different trucks - sometimes on the same truck)

Future

- Chuffing/synchronized sound

- Reverser Animation

What needs to be fixed/Updated with Coding

- BTU

- Coal and Water consumption

- Stoker/Hand Fired

- Working Blower

- Factor of Adhesion

- Steam Locomotive Wheel Slip Animation Needs to be Retarded to Behave More Prototypical-

- Blow down for both sides of locomotive simultaneously

- Feed Water Heaters/injectors

- Updated Fire Modeling Physics

Eventually would like coded

- Working boosters

- Steam and smoke effected by cold or weather

- More then one whistle/Horn button

- More Light Switches to Accommodate Class Lights.

If anyone else can think of more please feel free to add.

Brandon

Don't forget oil firing! Not sure if that counts with "Updated Fire Modeling Physics"...

#35

Posted 20 January 2021 - 05:31 PM

Brandon

Log In

Log In Register Now!

Register Now! Help

Help