UIC (International union of railways) has the rule UIC 544-1 (Brakes - Braking performance) with Annex B.1 for verifying the effect of the brakes.

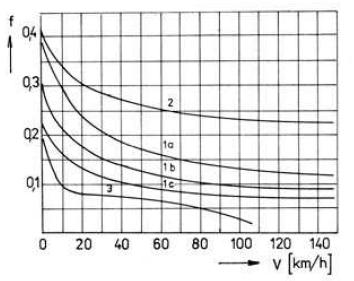

The brake performance is evaluated in a graph by plotting the calculated net brake ratio od car (or sum of the net brake ratio cars of train) on the speed curve. The intersection then shows the required distance to stop.

Usually I check the correct setting of the brakes on my vehicles (.eng, .wag) - especially the MaxBrakeForce parameter.

In the OR on a straight track, the tested train will start at the required speed. Then I reset the odometer at the same time and apply the full brake. I'll wait for the train to stop completely and read the distance traveled from the odometer.

I then compare this distance with the calculated distance from the UIC 544-1 graph. The result shows how well my brakes are set (braking force, brake reaction time - brake distributors, valves, equipment etc.).

Because I'm also interested in American locomotives and cars, I know that there is an AAR (Association of American Railroads) instead of UIC. I can't find a similar rule or graph for AAR (Verification of the effect of the brakes using the net brake ratio and stopping distance at different speeds).

Has anyone seen anything like this?

Attached File(s)

-

Nomograms.zip (819.56K)

Nomograms.zip (819.56K)

Number of downloads: 365

Log In

Log In Register Now!

Register Now! Help

Help