Slipping and Sliding Modelling wheel slip and wheel slide prevention systems

#1

Posted 19 June 2020 - 01:48 PM

Anti-Slip

( 1 ) Sanding [from early railways to the present]

Sanding is possible in Open Rails, I am not sure if there is any limit on the amount of sand available. There were variations in real-life such as gravity sanding, steam sanding and compressed air sanding. There does not seem to be much need to differentiate between them in the simulator.

( 2 ) Anti-slip brakes [1950s-1970s]

These were common on diesel and electric locomotives built in UK from the 1950s to the 1970s. Were they used elsewhere? They worked by putting 10 or 15 psi of air into the locomotive brake cylinders when the driver pressed a button (often on the throttle handle). This brief application of brakes gripping the wheel was intended to stop it from spinning.

( 3 ) Anti-slip control [1970s onwards]

When the start of a slip is sensed the electronics reduce the power supplied to the traction motors until the risk of slipping has ended, power then being restored to the level set on the throttle in so far as is possible without slipping. This is the arrangement that the MSTS Antislip ( ) is intended to produce. In OR this not only reduces the power to the traction motors, but physically moves the throttle handle to a lower setting. The throttle then remains at this lower setting until notched up again by the driver. We perhaps need to improve on how this works in Open Rails or possibly replace it with an ORTSAntislip ( ) that works as it should.

( 4 ) Three-phase a.c. traction motors with variable frequency control [1980s onwards]

Due to the way in which these motors are controlled by the supply frequency they are much less likely to slip than d.c. motors, single-phase motors or mechanical transmissions. There perhaps should be some way to represent this in OR. (The Italians had a three-phase system early in the 20th century – but the control of the motors was a little more crude at that time, so I would guess those trains were prone to slipping during acceleration.)

Anti-Slide

( 1 ) Variable Brake Force

In order to provide sufficient brake power for loaded vehicles, without causing empty vehicles to experience wheel slide, some braking systems can vary the brake force according to the load. This can be modelled in OR using the freight and load animation features.

( 2 ) Wheel Slide Prevention (WSP)

Vehicles fitted with modern disc brake systems are fitted with wheel slide prevention systems. These systems work rather like the anti-slip prevention systems described above – by sensing when a skid is likely to occur and reducing the brake force on that vehicle. This is a feature that could be added in Open Rails, possibly as ORTSAntislide ( ).

(An interesting early attempt at a WSP was used when EP brakes were introduced on the London Underground – cars were fitted with accelerometers which would reduce the pressure in the brake cylinder of a car that was decellerating too quickly during service braking.)

#2

Posted 19 June 2020 - 11:55 PM

darwins, on 19 June 2020 - 01:48 PM, said:

Sanding is possible in Open Rails, I am not sure if there is any limit on the amount of sand available. There were variations in real-life such as gravity sanding, steam sanding and compressed air sanding. There does not seem to be much need to differentiate between them in the simulator.

However apart from the impact on adhesion, I am not sure that there is value in looking at other forms of sanding, as other impacts would probably be minimal.

For example, for a steam sander, what would the typical steam consumption be, how often would sand supply be exhausted in a run, what is typical consumption of sand?

#3

Posted 20 June 2020 - 12:28 AM

Quote

I think we agree on that one. ("Not much need to differentiate between them...") So if we consider sanding as a task completed, perhaps we should move on to other items on the list. :)

#4

Posted 20 June 2020 - 10:00 AM

Although, the motor cars usually HAS sand equipment(bunkes, pipes, ejectors and elestric controls), it is used more rarely, than LowAcc switch.

This is because EMU has frequent stops, maximal acceleration so this process have to be automated, to make driver's work more easy.

In MSTS such cab control was declared (InHiLowAcceleration,IIRC), but trying to use it crashed the game immidiatly.

In Locos, the anti-slip system (before 1980th it was based in differential-relays, not electronics) can reduce current, sending ONLY to that group of Traction Motors(say 1,3,5 or 2,4,6-th axles), one of which started slipping, so remaining TM continues to produce full tractive effort with their wheels. But driver HAD to wtch the ammeter gauge and note the conditions, when wheelslip is likely to occur under particular conditions(mass of train, track's gradient, weather, curent, voltage in catenary, oil on rails, season(lives,snow,ice on rails))

In wagons, whose load changes frequently (same EMUs), the autoregime equipment tunes setting of Triple Walve (BC pressure,related to TP pressure drop), according the load's mass, every time, the doors are closed.

In wagons with rare changing load(say, never during particular ride - freight cars, for example), the mode of TW (empty/loaded/mountain/plain) is switched manually by the lever(s) under wag's body.

#5

Posted 20 June 2020 - 11:33 AM

Automatic acceleration in EMUs is a whole area that is yet to be developed. It can be faked in OR by using tractive force curves. I know the London Underground trains had the type of low acceleration switch that you describe.

I now want to check if this was also present on mainline EMUs in UK.

As a workaround in OR eng files I set 'Series' to low acceleration and 'Parallel' to fast acceleration:

Quote

For normal acceleration use the ‘Full Parallel’ notch.

For low adhesion conditions use ‘Full Series’ until speed is above about 15 to 20 mph.

#6

Posted 20 June 2020 - 11:47 AM

2. offtop:

#7

Posted 20 June 2020 - 06:50 PM

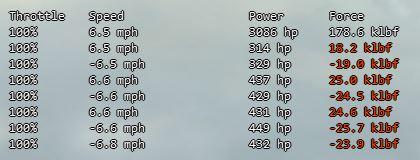

In my recent playing, I especially have to agree with darwins' third point on anti-slip; if Open Rails is to be realistic, wheel slip control really needs to reduce power without physically moving the throttle handle. Manually needing to bring the throttle back up after wheelslip occurs is both tedious and unrealistic. Wheel slip control should be entirely automatic.

This only causes more trouble when you consider that the current form of wheel slip control only works on the front locomotive. When the front locomotive slips, the reduction in throttle position causes all locomotives to reduce power, even if those locomotives weren't slipping! Conversely, if a trailing locomotive is slipping, but the front locomotive isn't, nothing will be done to stop that trailing locomotive from slipping, even if it has anti-slip enabled! This behavior can make some trains very hard to drive effectively, as (ironically) the slip system just won't allow for optimal power output (which goes against the whole point of an anti-slip system) and constant micro-management of the throttle handle is the only way to keep the train in check.

In an extreme case, it is entirely possible to have everything except the front unit slipping wildly out of control with no reduction in throttle setting anywhere in the system.

(All of these locomotives have AntiSlip ( 1 ), and all are modern units, so slipping should be incredibly minimal even with full throttle set.)

It doesn't help that this doesn't reflect real life at all, as each real-life locomotive will individually control its slipping to maintain optimal traction, and a more advanced anti-slip simulation would need to respect this behavior. However, that would definitely require some way for each locomotive to have some distinction between the throttle position and the actual power setting it's trying to output (like adding a 'generator field' setting, if you will), such that the throttle setting doesn't directly control the tractive output. Indeed, many real life wheel slip control systems operate entirely at the generator level, changing nothing about the engine RPM or throttle setting.

While adding a layer of complexity, that complexity is needed for "proper" anti-slip. And from what I read, such a feature would be useful in numerous other ways as well. I know I'd appreciate modeling of generator field so I could have more control over how quickly locomotives load and unload, as opposed to relying on changing the engine RPM rate of change (and that doesn't even affect how long it takes for power to reduce, it only changes how power increases!) And if someone doesn't want to bother setting that up, they can just use the configuration we already have, there's no need to remove the functionality that is already present.

I also wanted to add that sanding isn't all said and done in its current form. Many locomotives have automatic sanding as part of their wheel slip control. So when slip is detected, sand is automatically applied to that one locomotive for a few seconds to mitigate the slip faster than just power reduction alone could do. Granted, not everything has automatic sanding, and like everything else here, the specifics vary between models (my context is really only modern American diesel electrics). Should any of this be added to the game, there should definitely be individual parameters for a lot of this to be toggled on and off as appropriate. (With the underlying assumption that any changes should be optional, but there for those who opt-in to edit their .eng files.)

Now I don't expect such levels of realism that we start to attempt to model the electrical system and monitor motor voltages and amperages to see if anything is slipping and then this and that...that's the kind of thing TSW tries to do (foolishly?) and is way overkill for our purposes here. I just feel OR needs something smarter than "if lead locomotive slips, move throttle handle back" to complement the already smart advanced adhesion model.

#8

Posted 20 June 2020 - 11:05 PM

Quote

I have. Thanks for that.

The reason for rate switch on Underground trains in London is that about half of the Underground is above the ground - so the units do have to go out into rain, ice, snow and leaves.

I am told there was no rate switch on mainline EMU sets you either shut off power and opened up again or tried to slow down the notching by moving the controller back to the first position and then forward again - on these controllers moving to first position stopped the notching up process and the train remained in whatever notch it was in at that time until the driver advanced the controller to a higher position. I have attached a short description of the development of EMU controllers in UK. Anyway all this talk about EMU controllers is slightly going off topic.

Attached File(s)

-

EMU Control Systems in Open Rails.pdf (44.57K)

EMU Control Systems in Open Rails.pdf (44.57K)

Number of downloads: 414 -

EMU Brake Systems in Open Rails.pdf (52.61K)

EMU Brake Systems in Open Rails.pdf (52.61K)

Number of downloads: 432

#9

Posted 20 June 2020 - 11:55 PM

So we have -

Sanding - need to add option of automatic sanding for units with Anti-slip systems

Quote

Anti-slip brake - need to add to OR

Wheel-slip control system

- (a) needs to work in correct way

Quote

- (B) needs to be applied independently on each locomotive or power unit within the train

Quote

Variable Brake Force

As Weter mentioned there are two variations - (a) manual switch between high and low brake force and (B) continuously variable depending on load. Are both of these options currently possible in OR? Reading the "Physics Variation with Loads" section in the OR manual it is not clear to me how the first one would be set up.

Wheel-slide protection system - needs to be added

I take the point about not overcomplicating how wheel slip control (and wheel slide protection) are worked out. It would seem to make sense that whenever (due to adhesion model) a slip or a slide is about to occur that OR would temporarily reduce the tractive force or brake force on that vehicle. After all however it is worked out, that is the aim of the real thing.

#10

Posted 21 June 2020 - 01:39 AM

darwins said:

Our-too, however this is not always allowed to stay at such intermediate positions for long time, as I said. The running are usually: М,Ш,СП,П,ОП1,ОП2-ОПn (Maneurers,Shunt,Series-Parallel,Parallel,FieldWakening1,2-n)

(See verboose translation and explanations above)

Or, power handle has a special position, called something like "ФП" Fixation of Notching-up, or two notches 3A&3Б for directly moving MRC's shaft to one step-a-time in case of failure of automatic system.

Quote

Thank You. There's a little chance, that I'll have enough time to read that immidiatly, but, shure, that topic IS very interesting for me.

Is there some kind of Tech Doc's library at ET resource?

This could be useful for accumulating knowlege like that.

Quote

I agree, so I arranged it as a spoiler, BUT

I ask You and MODERATORS to move this material to topic, You quoted Yesterday,

OR, (maybe better?) to extend this topic's problematc till, say "automatic thrust and braking management systems of rolling stock and it's modelling by ORTS"?

afer all, this two themes looking so close, like Seame-twins, so it would be complex-to separate them.

darwins,

As addition to Your summary (Post#9)

I want to say about "Automatic impulse sanding" mode on modern locos, which can be turned on, if there's only chance, that wheelslip can occur, so driver can have less care, when to start sanding manually, and sand is used more efficient, rather when Shift+X(continious sanding) is engaged.

It was introduced earlyer, than auto-sanding, like pschlik said, but can be useful alternative.

In real world, driver HAVE to take care in turning off sanders, when loco is moving over switches, avoiding their damage by sand.

Log In

Log In Register Now!

Register Now! Help

Help