MaxBrakeForce Maching with real values

#1

Posted 20 January 2019 - 03:39 AM

On trains you have some text like this:

P: 73t

G: 61t

R: 94t

For engineering i use value of "p", but i must know of this is good way for give the right MaxBrakeForce ( 73kN )

In advance thanks,

Stijn

#3

Posted 21 January 2019 - 10:50 AM

ErickC, on 21 January 2019 - 01:53 AM, said:

ErickC, on 21 January 2019 - 01:53 AM, said:

For modern brake shoes.

Go back 50 years and instead of 38% of empty car weight you'd find (in North America) it was 60-70% with each railroad setting their own standard percentage. Apparently modern shoes grab the rim so much better than the old types they don't need as much force applied.

Which leads me to wonder... assume we have two cars from each era that weigh the same. if you use 38% and I use 70% what does OR do to produce what should be am identical braking effect?

#4

Posted 21 January 2019 - 12:08 PM

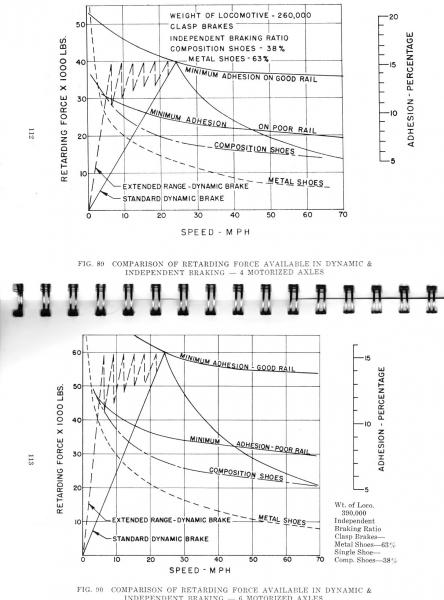

What would be nice, though, is if OR modelled the difference in overall behaviour. From what I've read, cast iron shoes are pretty worthless at high speeds but a little too effective at low speeds, whereas composition shoes are great at high speed but lose effectiveness at low speed.

You are correct that the numbers for unloaded care may not be correct depending on the era. Empty/load switches were not always a thing. In that case, you would use the loaded ratio, and remember that 25% is about as much adhesion as the shoe can possibly get on the wheel (much as with the wheel and rail).

#5

Posted 21 January 2019 - 04:00 PM

#6

Posted 21 January 2019 - 08:47 PM

I'll see what I can come up as far as curves go, but I doubt I'll be able to find much. "Management of Train Operations and Train Handling" quotes 33% COE for high friction composition shoes at 60 mph and 15% for low friction composition shoes (also at 60 mph).

#7

Posted 21 January 2019 - 09:06 PM

Excerpt from the manual 8.6.1 Brake Shoe Adhesion:

Quote

in WAG le - OR assumes the users assigned friction coe cient have been set at 20% friction

coe cient for cast iron brakes, and reverse engineers the braking force, and then applies the default

friction curve as the speed varies.

There is also a sample ORTSBrakeShoeFriction curve for composition brakes among other things.

#8

Posted 21 January 2019 - 09:33 PM

Note that both curves cross at low speeds (but it's more obvious on the 4-axle example).

Here's my question: the OR manual is really unclear about what this parameter does. Does it apply a coefficient to the maximum brake force value? Or will we need to create a coefficient curve, then multiply each y value by the nominal maximum brake force value calculated by the brake ratio?

While we're on the subject of brakes - this book has all kinds of charts for application and charging times for trains of varying lengths. If someone would be willing to turn this data into something that could be more or less universally applied (I'm guessing that a "pretty accurate for most cars" set of parameters could be compiled), I'd be more than willing to scan these charts (be advised there are a lot of them).

#9

Posted 21 January 2019 - 10:46 PM

ErickC, on 21 January 2019 - 09:33 PM, said:

ErickC, on 21 January 2019 - 09:33 PM, said:

This might shed some light onto your question.

#10

Posted 22 January 2019 - 10:52 AM

ErickC, on 21 January 2019 - 09:33 PM, said:

ErickC, on 21 January 2019 - 09:33 PM, said:

If someone would be willing to turn this data into something that could be more or less universally applied (I'm guessing that a "pretty accurate for most cars" set of parameters could be compiled), I'd be more than willing to scan these charts (be advised there are a lot of them).

Highlights are mine.

Yes! I'm delighted that Peter has compiled a lot of information on the theory but I'm not (yet) at a place where I can make sense of it all and apply it to a 1940's US boxcar's .wag.

What I need is a "starter set" of parameters and values that I can drop in for now while I do my homework on the theory behind it all. The "starter set" needs to be convertible back into the parameters of the various formulas so one can go from there to calculating values for other cars.

Log In

Log In Register Now!

Register Now! Help

Help