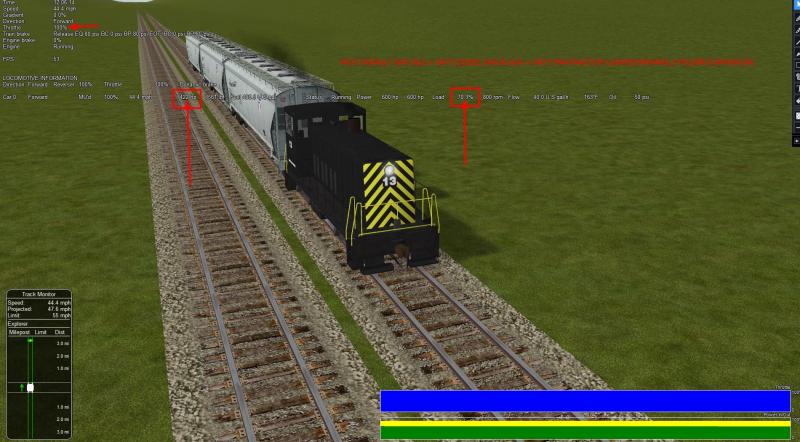

1. Default MSTS eng file produces power to the rail - Notch8 - in the normal 90% range and is proportionally correct at all other power notches.

2. Default MSTS eng file with ORTSDieselEngines block ( via OpenRails folder/eng include file/Common.inc folder ) also produces normal power to the rails at Run 8 and proportionally correct at all other notches.

3. Adding the ORTSMaxTractiveForceCurves in any file configuration results in reduced power to the rails at Notch8, in the range of 50% (observed as low as 42% and as high as 70%), also proportionally lower at all other notches.**

4. All diesel locomotives tested, all routes, no log warning or error is observed.

5. Tests in the screenshot were with the locomotive and curve given in the manual on page 118, Sec. 8.1.4.1 ( see files used inserted in post )

**Note: file configurations --- MSTS default eng file with ORTSMTFcurves added to it ( No OpenRails folder); ORTSMTFcurves added to ORTSDieselEng block ( as shown Below) + MSTS default eng file; and ORTSMTFcurves only ( OpenRails folder/Common.inc) + MSTS default eng file.

Re-reading what I posted (and postings in another thread), I don't believe one can conclusively state that the fault lies with the ORTSMTF curves, it could very well be a problem with the Advanced Adhesion model. I'm thinking how to test that? Anyone know the advanced adhesion code?...that's not something I could tackle.

Comment ( Standard ORTS Diesel Engine for GE_70Ton Locomotive )

Comment ( Performance Ratings == Gross HP 700 == Traction HP 600 == 23605lb CTE == 41590lb MTE )

Comment ( include ( "..\\..\\Common.inc\\Locomotives\\GE_70Ton.inc" ) )

ORTSDieselEngines ( 1

Diesel(

IdleRPM ( 315 )

MaxRPM ( 800 )

StartingRPM ( 275 )

StartingConfirmRPM ( 350 )

ChangeUpRPMpS ( 65 )

ChangeDownRPMpS ( 35 )

RateOfChangeUpRPMpSS ( 25 )

RateOfChangeDownRPMpSS ( 15 )

MaximalPower ( 521.990kW )

IdleExhaust ( 1.2 )

MaxExhaust ( 2.3 )

ExhaustDynamics ( 2.2 )

ExhaustDynamicsDown ( 0.8 )

ExhaustColor ( 20161819 )

ExhaustTransientColor ( 40212324 )

DieselPowerTab (

0 0

350 55928

415 111855

480 167783

545 223710

610 279638

675 335565

740 391493

800 447420

)

DieselConsumptionTab (

0 0

315 37.9

800 151.4

)

ThrottleRPMTab (

0 315

12.5 350

25 415

37.5 480

50 545

62.5 610

75 675

87.5 740

100 800

)

DieselTorqueTab (

0 0

315 2951

800 23605

)

MinOilPressure ( 20 )

MaxOilPressure ( 50 )

MaxTemperature ( 120 )

Cooling ( 3 )

TempTimeConstant ( 720 )

OptTemperature ( 71 )

IdleTemperature ( 55 )

)

)

ORTS (

ORTSEmergencyCausesThrottleDown ( 1 )

ORTSWheelSlipCausesThrottleDown ( 1 )

ORTSMainResChargingRate ( 0.237 )

ORTSBrakePipeChargingRate ( 40 )

TrainPipeLeakRate ( 0.0833 )

ORTSEngineBrakeReleaseRate ( 38 )

ORTSEngineBrakeApplicationRate ( 34 )

ORTSBrakePipeTimeFactor ( 0.003 )

ORTSBrakeEmergencyTimeFactor ( 0.1 )

ORTSBrakeServiceTimeFactor ( 1.009 )

)

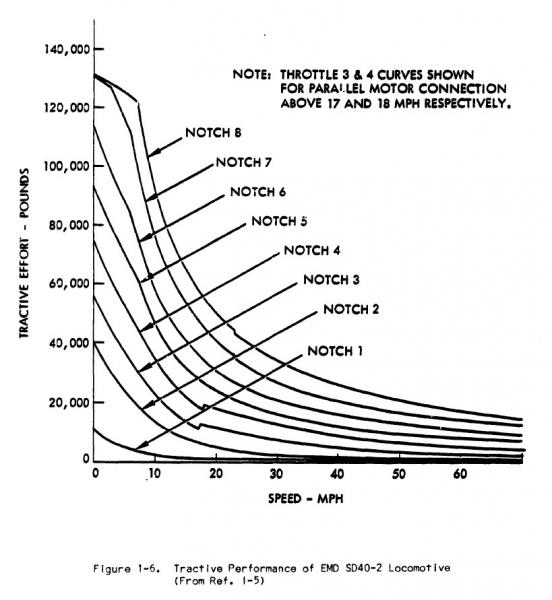

ORTSMaxTractiveForceCurves ( 0 ( 0 0 50 0 )

.125 (

0 23125

0.3 23125

1 6984

2 3492

5 1397

10 698

20 349

50 140 )

.25 (

0 46250

0.61 46250

1 27940

2 13969

5 5588

10 2794

20 1397

50 559 )

.375 (

0 69375

0.91 69375

2 31430

5 12572

10 6287

20 3143

50 1257 )

.5 (

0 92500

1.21 92500

5 22350

10 11175

20 5588

50 2235 )

.625 (

0 115625

1.51 115625

5 34922

10 17461

20 8730

50 3492 )

.75 (

0 138750

1.82 138750

5 50288

10 25144

20 12572

50 5029 )

.875 (

0 161875

2.12 161875

5 68447

10 34223

20 17112

50 6845 )

1 (

0 185000

2.42 185000

5 89400

10 44700

20 22350

50 8940 )

)

include ( "..\\bc13ge70tonner.eng" ) Wagon ( include ( "..\\..\\Common.inc\\Locomotives\\Std_TypeF_Coupler.inc" ) include ( "..\\..\\Common.inc\\Locomotives\\Std_Loco_Brakes.inc" ) ORTSAdhesion ( ORTSCurtius_Kniffler ( 7.5 44 0.161 0.7 ) ) ORTSAdhesion ( ORTSSlipWarningThreshold ( 70 ) ) ORTSBearingType ( Roller ) ORTSDavis_A ( 920.72 ) ORTSDavis_B ( 20.8947 ) ORTSDavis_C ( 5.485595 ) Comment ( == Assumptions -Locomotive diesel/electric - speed - 55mph (89km/h), Roller Bearing, 4 axles, frontal area - 10.6m2, WagonWeight - 63.5 ton (metric), Drag 0.90 == ) ) Engine ( Effects ( DieselSpecialEffects ( Exhaust1 ( -0.405 4.3 -0.417 0 1 0 0.13 ) ) ) include ( "..\\..\\Common.inc\\Locomotives\\GE_70Ton_TEST.inc" ) )

Log In

Log In Register Now!

Register Now! Help

Help