Gearbox feature

#41

Posted 16 August 2013 - 11:29 AM

Cheers, Markus

#42

Posted 16 August 2013 - 12:32 PM

Matej Pacha, on 16 August 2013 - 02:38 AM, said:

Matej Pacha, on 16 August 2013 - 02:38 AM, said:

Just a small comment, diesels produce good torque from __VERY__ low revs (unlike a petrol engine) one has no difficulty in starting a diesel car even a Landcruiser in 1st gear without using the clutch. The only requirement being one is on a flat or down hill as the starter will not normally drive such a vehicle up a hill.

Quote

Actually, I didn't make any difference between mechanic and hydraulic setting, because I don't know how to handle the hydraulic one correctly. Let's say that this is a part of my main tasks for v1.0.

If required I can send some information on the performance of hydraulic couplings including torque convertors which should help with the mathematical modelling. The torque handling ability of such couplings is proportional to the square of the rpm. The items are from "Marks Standard Handbook for Mechanical Engineers" one of THE best books on how machinery operates, although VERY expensive. Also there is an item (a graph) from Voith.

One of the major reasons for the wide use of such couplings in industry both straight and torque convertors is reduced maintence and a great improvement reliabilty. Torque amounts in the 1000's of ft pounds and higher range being VERY difficult to control.

Lindsay

#43

Posted 16 August 2013 - 12:45 PM

markus_GE, on 16 August 2013 - 11:29 AM, said:

markus_GE, on 16 August 2013 - 11:29 AM, said:

Cheers, Markus

This has been done is some cars using an electric transmission, including a gas turbine car in the Le man's 24 hour (from memory it was a Chrysler, Note 1). This was/is done to reduced the size and weight of the transmission.

This is not usually an issue though with rail vehicles, the weight of the altenator being small compared with the overall weight of the vehicle.

Note 1, It has a 500 bhp gas turbine, the transmission both altenator, energy storage unit and motors weighed less than 100 kgs. The total power to the wheels was around 700 bhp, being 500 from the main engine and 200 from the energy storage unit. There was an article in the "New Scientist" about it sometime late 1980's I think.

Lindsay

#44

Posted 16 August 2013 - 12:52 PM

Cheers, Markus

#45

Posted 16 August 2013 - 02:31 PM

#46

Posted 16 August 2013 - 06:41 PM

markus_GE, on 16 August 2013 - 12:52 PM, said:

markus_GE, on 16 August 2013 - 12:52 PM, said:

Cheers, Markus

There would unlikely be a fuel saving, the engines in both EMD and GE are pushed quite hard for a continous duty engine, ie the power/litre/100's rpm is quite high and dropping the revs would mean the engines would have to be bigger to get the same power.

Also these loco's are already quite fuel economic, the actual fuel used per hour being quite low for the power produced. Note this is common in engines with high volume cylinders as its easier to get a better burn of the fuel in a large cylinder.

Have a look at a cross section of a DE loco, one finds the main altenator is quite small compared to the size of the engine.

Lindsay

#47

Posted 16 August 2013 - 07:10 PM

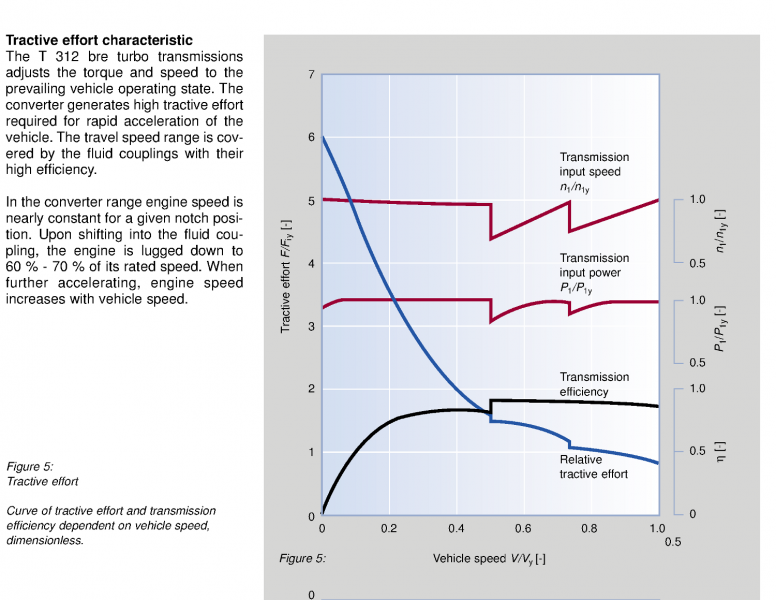

Image is from the Voith publication "T312 br turbo transmission" page 4. From Voith's web site.

Lindsay

#48

Posted 16 August 2013 - 07:18 PM

Gear change points are just over 80kph and around 130kph, transmission efficiency in the cruising gears is stated as 94 to 95%.

Lindsay

#49

Posted 17 August 2013 - 02:49 AM

As for how big the alternator, I guess, the smaller it is, the "easier" it might be moveable (less weight in Motion = less Initial inertia), but again, a lack of knowledge on my side.

Cheers, Markus

#50

Posted 17 August 2013 - 03:16 AM

Lindsayts, on 16 August 2013 - 07:18 PM, said:

Lindsayts, on 16 August 2013 - 07:18 PM, said:

Gear change points are just over 80kph and around 130kph, transmission efficiency in the cruising gears is stated as 94 to 95%.

Lindsay

Very nice lines in the previous post of yours. However, because the fluid coupling is there, if the throttle is closed RPM will decay regardless of vehicle speed because the engine is no longer providing the required force to drive the coupling.

Log In

Log In Register Now!

Register Now! Help

Help